The integration of embedded rigid-flex components in space-constrained smart watches has revolutionized the design and functionality of these wearable devices.

Smart watches have become essential gadgets for tracking health metrics, receiving notifications, and performing various tasks on the go.

To ensure that these devices remain compact yet powerful, manufacturers are turning to embedded rigid-flex components.

The Evolution of Smart Watches

Smart watches have evolved from mere time-telling devices to sophisticated wearables that can track fitness activities, monitor heart rates, and even make payments.

The demand for smaller, sleeker designs with increased functionality has driven the need for innovative solutions in component integration.

Embedded rigid-flex components offer a way to pack more features into a limited space without compromising on performance.

Understanding Embedded Rigid-Flex Components

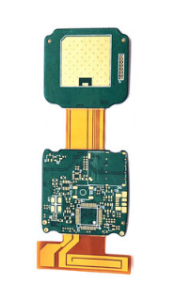

Embedded rigid-flex components combine the benefits of rigid and flexible PCB (Printed Circuit Board) technologies.

Rigid PCBs provide structural support and stability, while flexible PCBs allow for intricate designs and flexibility.

By integrating both types of boards, manufacturers can create compact yet robust assemblies that can withstand the rigors of daily wear.

Benefits of Embedded Rigid-Flex Components in Smart Watches

- Space Efficiency: One of the primary advantages of embedded rigid-flex components is their ability to reduce the overall size of the device.

This is crucial for smart watches, where space is limited due to the small form factor.

By integrating components into a single, compact unit, manufacturers can maximize the available space for other features. - Improved Durability: Smart watches are subjected to constant movement and wear.

Embedded rigid-flex components offer greater resistance to mechanical stress, making them ideal for devices that are worn on the wrist.

The flexible portions of the PCB can absorb shocks and vibrations, while the rigid sections provide stability and protection for delicate components. - Enhanced Reliability: The integration of rigid-flex components eliminates the need for multiple interconnects and solder joints, reducing the risk of failure.

By streamlining the assembly process and minimizing points of potential weakness, manufacturers can ensure higher reliability and longevity for smart watches. - Design Flexibility: Embedded rigid-flex components allow for more innovative and intricate designs.

Manufacturers can create custom shapes and configurations to fit the unique contours of a smart watch, optimizing space utilization and enhancing aesthetics.

Future Trends and Applications

As the demand for smaller and more feature-rich smart watches continues to grow, the use of embedded rigid-flex components is expected to become even more prevalent.

Innovations in materials and manufacturing techniques are enabling thinner and more flexible PCBs, further pushing the boundaries of design possibilities.

In addition to smart watches, embedded rigid-flex components have applications in a wide range of industries, including medical devices, automotive electronics, and wearable technology.

The versatility and reliability of these components make them well-suited for devices that require high performance in compact form factors.

In conclusion, the adoption of embedded rigid-flex components in space-constrained smart watches marks a significant step forward in wearable technology.

By combining the best attributes of rigid and flexible PCB technologies, manufacturers can create devices that are not only compact and durable but also highly functional and reliable.

As this trend continues to evolve, we can expect to see even more innovative designs and enhanced capabilities in the next generation of smart watches.