In the ever-evolving world of LED lighting systems, the quest for efficiency, durability, and compactness is relentless.

High-density LED lighting systems are becoming increasingly popular due to their energy-saving benefits and versatility in various applications.

One crucial component that plays a significant role in the performance of these systems is the Printed Circuit Board (PCB).

Specifically, the emergence of thermally stable rigid-flex PCBs has been a game-changer, offering enhanced reliability and performance in high-density LED lighting applications.

The Demand for High-Density LED Lighting Systems

As the demand for energy-efficient lighting solutions continues to rise, high-density LED lighting systems have gained remarkable traction in both residential and commercial sectors.

These systems are sought after for their ability to deliver bright and uniform illumination while consuming less power than traditional lighting sources.

From automotive lighting and backlighting applications to architectural lighting and display panels, high-density LED lighting systems have proven to be versatile and reliable solutions.

Introduction to Rigid-Flex PCBs

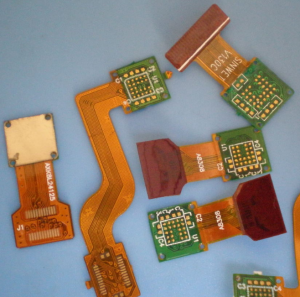

Rigid-flex PCBs combine the advantages of rigid and flexible circuit boards, offering a unique solution for applications that require both mechanical flexibility and high reliability.

These specialized PCBs are designed to withstand bending, folding, and twisting without compromising the integrity of the circuit, making them ideal for space-constrained designs and applications subject to mechanical stress. In high-density LED lighting systems, where space optimization and thermal management are critical, rigid-flex PCBs have become a preferred choice.

Enhanced Thermal Stability in Rigid-Flex PCBs

Thermal management is crucial in LED lighting systems to ensure optimal performance and longevity of the LEDs.

Heat dissipation and thermal stability play a significant role in preventing performance degradation and extending the lifespan of the LED modules.

Traditional PCB materials may struggle to provide adequate thermal stability in high-density LED lighting systems, leading to overheating and premature failure.

Thermally stable rigid-flex PCBs address this challenge by incorporating advanced materials that offer superior thermal conductivity and heat dissipation properties.

By enhancing the PCB’s ability to dissipate heat effectively, thermally stable rigid-flex PCBs help maintain the optimal operating temperature of the LED components, reducing the risk of thermal runaway and ensuring consistent performance over time.

Benefits of Thermally Stable Rigid-Flex PCBs in LED Lighting Systems

The adoption of thermally stable rigid-flex PCBs in high-density LED lighting systems offers a range of benefits that contribute to improved performance and reliability:

- Enhanced Heat Dissipation: Thermally stable rigid-flex PCBs facilitate efficient heat dissipation, reducing the risk of overheating and improving the overall thermal management of the LED lighting system.

- Space Optimization: The compact and flexible nature of rigid-flex PCBs allows for space-saving designs, making them ideal for applications where size constraints are a concern.

- Mechanical Reliability: Rigid-flex PCBs offer superior mechanical reliability, allowing them to withstand bending and flexing without compromising the integrity of the circuit connections.

- Longevity: By maintaining optimal operating temperatures and reducing thermal stress on the LED components, thermally stable rigid-flex PCBs help extend the lifespan of the LED lighting system.

Conclusion

Thermally stable rigid-flex PCBs have emerged as a key enabler of high-density LED lighting systems, offering enhanced thermal stability, reliability, and performance.

By addressing the challenges associated with heat dissipation and mechanical flexibility, rigid-flex PCBs play a vital role in optimizing the efficiency and longevity of LED lighting solutions.

As the demand for energy-efficient and compact lighting systems continues to grow, the development and adoption of thermally stable rigid-flex PCBs are set to reshape the landscape of high-density LED lighting applications, driving innovation and sustainability in the lighting industry.