Revolutionizing Wearable Technology with Durable Rigid-Flex PCBs for Washable Smart Clothing and E-Textiles

In the realm of wearable technology, the integration of electronics into clothing has opened up a world of possibilities.

From fitness trackers to smart garments that monitor vital signs, the marriage of textile and technology continues to evolve.

A crucial component enabling this progress is the development of durable rigid-flex PCBs (Printed Circuit Boards) that are specifically designed for washable smart clothing and e-textiles.

These innovative PCBs are revolutionizing the wearable tech industry by offering flexibility, durability, and longevity in electronic components integrated into fabrics.

The Rise of Smart Clothing and E-Textiles

Smart clothing and e-textiles represent a new frontier in wearables.

These garments are embedded with electronic components that gather data, provide feedback, and offer various functionalities to enhance the wearer’s experience.

From smart athletic wear that tracks performance metrics to adaptive clothing for individuals with disabilities, the applications of smart textiles are vast and diverse.

However, integrating electronics into fabric poses several challenges, primarily concerning flexibility, durability, and washability.

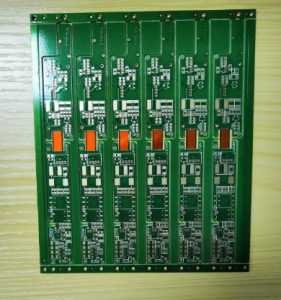

Introducing Durable Rigid-Flex PCBs

One of the key solutions to the challenges faced in smart clothing design is the use of rigid-flex PCBs.

Unlike traditional rigid PCBs that are stiff and inflexible, rigid-flex PCBs combine the benefits of rigid and flexible circuits in a single board.

This hybrid design allows the PCB to bend and conform to the contours of the fabric while providing the necessary structural support for electronic components.

By using durable materials that can withstand bending and washing cycles, rigid-flex PCBs ensure the longevity and reliability of the integrated electronics in smart clothing and e-textiles.

Benefits of Durable Rigid-Flex PCBs in Wearable Technology

The adoption of durable rigid-flex PCBs in wearable technology offers several advantages.

Firstly, these PCBs provide the flexibility needed for electronics to move and stretch with the fabric, ensuring comfort and functionality for the wearer.

Additionally, the durability of rigid-flex PCBs enhances the longevity of the electronic components, reducing the need for frequent repairs or replacements.

Moreover, the washability of these PCBs enables easy maintenance of smart clothing, making them suitable for everyday use.

Innovative Applications of Durable Rigid-Flex PCBs

The integration of durable rigid-flex PCBs has enabled the development of innovative smart clothing and e-textile applications.

For example, fitness trackers woven into athletic wear can monitor heart rate and activity levels without compromising comfort or performance.

Similarly, medical garments embedded with sensors can continuously monitor vital signs and alert healthcare providers in real-time.

The versatility of rigid-flex PCBs allows designers to explore new possibilities in wearables, creating functional and fashionable tech-enabled apparel.

Future Trends in Washable Smart Clothing

As technology continues to advance, the future of washable smart clothing and e-textiles looks promising.

Innovations in material science and electronics manufacturing are driving the development of even more durable and flexible PCBs for wearable applications.

With the integration of sensors, actuators, and communication modules into fabrics, the next generation of smart clothing will offer enhanced connectivity, comfort, and performance.

The convergence of fashion and technology is set to redefine how we interact with our clothing and the world around us.

Conclusion

Durable rigid-flex PCBs are at the forefront of enabling washable smart clothing and e-textiles, revolutionizing the wearable technology landscape.

By combining flexibility, durability, and washability in electronic components integrated into fabric, rigid-flex PCBs are paving the way for innovative and practical applications in smart garments.

As the demand for functional and fashionable wearables continues to grow, the importance of durable PCBs in enhancing the performance and longevity of electronic textiles cannot be overstated.

Embracing the potential of rigid-flex PCBs is key to unlocking the full potential of wearable technology and ushering in a new era of interconnected, intelligent clothing.