In the fast-paced world of smart devices, the demand for improved functionality and compact design is ever on the rise.

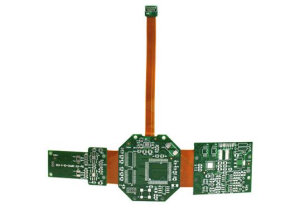

One innovative solution that has emerged to address these challenges is the use of Flex-Rigid PCB techniques.

By integrating flexible and rigid circuit boards into a single unit, manufacturers can eliminate the need for connectors in smart devices, leading to enhanced reliability, durability, and performance.

In this article, we will explore the benefits of Flex-Rigid PCB techniques and how they are revolutionizing the design and manufacturing of smart devices.

The Evolution of Flex-Rigid PCB Technology

Flex-Rigid PCB technology represents a significant advancement in the field of electronics manufacturing.

Traditional PCBs are rigid and limited in terms of design flexibility, making them less suitable for compact and portable devices.

By combining flexible and rigid substrates into a single board, Flex-Rigid PCBs offer the best of both worlds – the durability and reliability of rigid boards and the flexibility of flexible circuits.

Key Benefits of Flex-Rigid PCB Techniques

- Miniaturization: One of the key advantages of Flex-Rigid PCB techniques is their ability to enable compact and space-saving designs.

By eliminating connectors, designers can reduce the overall size of the device, making it more portable and aesthetically pleasing. - Reliability: Connectors are often a point of failure in electronic devices due to wear and tear over time.

By eliminating connectors and integrating the connection directly into the PCB, the reliability of the device is significantly improved, leading to longer product lifecycles and fewer maintenance issues. - Cost-Effectiveness: While the initial cost of implementing Flex-Rigid PCB techniques may be higher than traditional methods, the long-term benefits in terms of reduced maintenance and replacement costs far outweigh the initial investment.

Applications of Flex-Rigid PCBs in Smart Devices

Flex-Rigid PCB techniques are being increasingly adopted in a wide range of smart devices, including smartphones, wearables, tablets, and IoT devices.

These technologies allow for seamless integration of components, improved signal integrity, and enhanced mechanical performance, making them ideal for demanding applications where space and reliability are crucial.

Design Considerations for Flex-Rigid PCBs

When designing smart devices with Flex-Rigid PCBs, several key considerations need to be taken into account.

These include the selection of materials, routing of traces, and electrical performance optimization.

Working closely with experienced PCB designers and manufacturers is essential to ensure that the final product meets the required specifications and performance standards.

Conclusion

Flex-Rigid PCB techniques offer a versatile and reliable solution for eliminating connectors in smart devices.

By integrating flexible and rigid circuit boards into a single unit, manufacturers can achieve compact designs, enhanced reliability, and improved performance.

As the demand for smaller, more powerful smart devices continues to grow, the adoption of Flex-Rigid PCB technology is expected to increase, driving innovation in the electronics industry.