The automotive industry is increasingly adopting Internet of Things (IoT) technology to enhance vehicle performance and safety.

One significant application area is the use of IoT sensors in vehicles to collect data and enable advanced functionalities.

In such a demanding environment, it is crucial to ensure that these sensors are capable of withstanding harsh conditions while maintaining optimal performance.

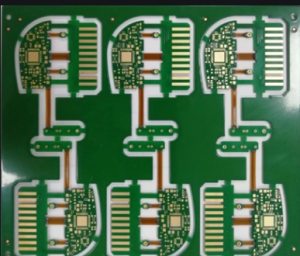

This is where robust rigid-flex designs play a vital role in ensuring the durability and functionality of automotive IoT sensors in challenging environments.

Importance of Robust Rigid-Flex Designs

Robust rigid-flex designs are essential for automotive IoT sensors as they offer a combination of flexibility and durability.

In the automotive industry, IoT sensors are exposed to various environmental factors such as temperature fluctuations, vibrations, moisture, and mechanical stress.

Traditional rigid PCBs may not be sufficient to withstand these conditions, making rigid-flex designs the preferred choice for automotive applications.

Key Considerations for Designing Robust Rigid-Flex Circuits

- Material Selection: Choosing the right materials is critical for robust rigid-flex designs in automotive IoT sensors.

High-quality, flexible materials that can withstand extreme temperatures and harsh environments are essential for ensuring the longevity and performance of the sensors. - Structural Integrity: The design of rigid-flex circuits must prioritize structural integrity to prevent damage from mechanical stress and vibration.

Reinforcements such as stiffeners and support structures can enhance the overall durability of the sensor, ensuring reliable operation in challenging conditions. - Environmental Protection: Automotive IoT sensors are often exposed to moisture, dust, and other environmental hazards.

Implementing robust sealing and coating techniques can protect the circuitry from these elements, extending the sensor’s lifespan and reliability.

Challenges of Harsh Environments in Automotive IoT Sensors

Harsh environments pose several challenges for automotive IoT sensors, including:

- Temperature Fluctuations: Extreme temperatures can affect the performance and reliability of sensors.

Robust rigid-flex designs are essential for maintaining consistent operation in varying temperature conditions. - Vibrations and Mechanical Stress: Automotive IoT sensors are subjected to vibrations and mechanical stress during vehicle operation.

Ensuring that the rigid-flex design can withstand these conditions is crucial for long-term functionality. - Moisture and Contaminants: Water, dust, and other contaminants can impact sensor performance.

Effective sealing and protection measures are necessary to mitigate the risks posed by moisture and contaminants.

Benefits of Robust Rigid-Flex Designs for Automotive IoT Sensors

- Space Efficiency: Rigid-flex designs allow for compact and space-efficient sensor assemblies, ideal for automotive applications where space is limited.

- Reliability: The durability and robustness of rigid-flex designs enhance the overall reliability of automotive IoT sensors, reducing maintenance costs and downtime.

- Customization: Rigid-flex designs offer flexibility in customization to meet specific requirements of automotive IoT sensor applications, allowing for tailored solutions to be developed.

Conclusion

In conclusion, robust rigid-flex designs play a crucial role in ensuring the durability and performance of automotive IoT sensors in harsh environments.

By considering key factors such as material selection, structural integrity, and environmental protection, designers can create robust rigid-flex circuits that meet the demanding requirements of automotive applications. Implementing these designs not only enhances the reliability of IoT sensors but also contributes to improved vehicle performance and safety in challenging conditions.