The demand for smaller and smarter IoT devices with machine learning capabilities is driving the need for advanced printed circuit boards (PCBs) that can accommodate these requirements.

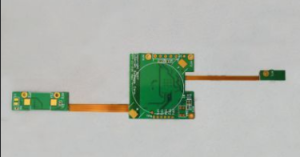

High-Density Rigid-Flex PCBs are emerging as a crucial technology for IoT edge nodes that incorporate TinyML capabilities.

These specialized PCBs offer a compact and versatile solution for integrating sensors, processors, and wireless connectivity in IoT devices while enabling the deployment of machine learning algorithms at the edge.

In this article, we will explore the advantages and applications of High-Density Rigid-Flex PCBs in the realm of IoT devices with TinyML capabilities.

The Advent of High-Density Rigid-Flex PCBs

High-Density Rigid-Flex PCBs represent a significant advancement in the field of printed circuit board technology.

These boards combine the benefits of rigid and flexible PCBs, offering a reliable and durable solution for IoT edge nodes with space constraints.

By leveraging advanced manufacturing techniques, High-Density Rigid-Flex PCBs enable designers to pack more components into a smaller footprint, making them ideal for IoT devices that require compact form factors.

Benefits of High-Density Rigid-Flex PCBs for IoT Edge Nodes

- Space Efficiency: One of the key advantages of High-Density Rigid-Flex PCBs is their space-efficient design.

By incorporating both rigid and flexible sections, these PCBs can be folded or bent to fit into tight spaces within IoT devices.

This space-saving feature is essential for miniaturized IoT products that demand high functionality in a limited physical volume. - Enhanced Reliability: High-Density Rigid-Flex PCBs offer enhanced reliability compared to traditional PCBs.

The combination of rigid and flexible materials improves the board’s resistance to mechanical stress, vibration, and thermal fluctuations, making them suitable for rugged IoT applications in harsh environments. - Signal Integrity: Maintaining signal integrity is critical in IoT devices with TinyML capabilities.

High-Density Rigid-Flex PCBs provide superior signal transmission characteristics, reducing signal interference and ensuring optimal performance of sensors, processors, and wireless modules integrated into the board.

Applications of High-Density Rigid-Flex PCBs in IoT Edge Nodes with TinyML

The integration of TinyML capabilities into IoT edge nodes opens up a myriad of innovative applications across various industries.

High-Density Rigid-Flex PCBs play a vital role in enabling these applications by providing a robust and efficient platform for implementing machine learning algorithms at the edge. Some potential applications include:

- Healthcare: IoT devices equipped with TinyML on High-Density Rigid-Flex PCBs can monitor vital signs, detect anomalies, and provide real-time health insights to users and healthcare professionals.

These devices can contribute to remote patient monitoring, personalized healthcare solutions, and early disease detection. - Smart Manufacturing: In the realm of Industry 4.0, IoT edge nodes with TinyML capabilities can optimize manufacturing processes, predict equipment failures, and enhance overall efficiency.

High-Density Rigid-Flex PCBs support the integration of sensors, actuators, and machine learning algorithms in smart manufacturing systems. - Smart Agriculture: By deploying IoT edge nodes with TinyML on High-Density Rigid-Flex PCBs, farmers can gather valuable data on crop health, soil conditions, and environmental factors.

This data can be analyzed locally to make timely decisions on irrigation, fertilization, and pest control, leading to increased crop yield and sustainability.

In conclusion, High-Density Rigid-Flex PCBs are revolutionizing the design and deployment of IoT edge nodes with TinyML capabilities.

These advanced PCBs offer a compact, reliable, and efficient solution for integrating machine learning algorithms into IoT devices, empowering a new wave of smart applications across diverse industries.

As the demand for smaller, smarter, and more powerful IoT devices continues to grow, High-Density Rigid-Flex PCBs will play a pivotal role in shaping the future of connected technologies.