In the realm of wearable technology, the integration of advanced solutions like AI-optimized rigid-flex PCB assembly has revolutionized the development of next-generation health monitoring devices. Wearable health monitors have rapidly evolved to offer more sophisticated features, allowing individuals to track vital health metrics in real-time. The use of rigid-flex PCBs, combined with artificial intelligence (AI) algorithms, has significantly enhanced the performance, versatility, and reliability of these devices. This article explores the benefits and applications of AI-optimized rigid-flex PCB assembly in the development of cutting-edge wearable health monitors.

The Evolution of Wearable Health Monitors

Wearable health monitors have become indispensable tools for individuals looking to monitor their health and fitness levels continuously. These devices can track a wide range of parameters, including heart rate, blood pressure, oxygen saturation, and physical activity. The integration of AI algorithms has further elevated the capabilities of these monitors by enabling more accurate data analysis and personalized insights.

Advantages of Rigid-Flex PCBs in Wearable Health Monitors

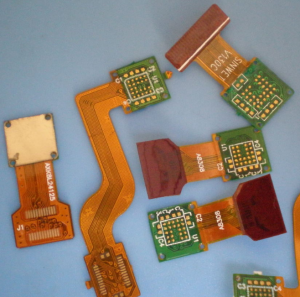

Rigid-flex PCBs offer a unique advantage in the design and implementation of wearable health monitors. These circuit boards are characterized by a combination of rigid and flexible PCB areas, allowing for greater design flexibility and compactness. The use of rigid-flex PCB assembly enables the creation of sleek and lightweight health monitors that can be comfortably worn throughout the day.

Enhancing Performance with AI Optimization

One of the key benefits of incorporating AI algorithms into wearable health monitors is the ability to optimize data processing and analysis. By leveraging AI techniques such as machine learning and pattern recognition, these devices can provide more accurate and personalized health insights to users. AI-optimized rigid-flex PCB assembly plays a critical role in ensuring the seamless integration and operation of these sophisticated algorithms within the device.

Applications of AI-Optimized Rigid-Flex PCB Assembly

The combination of AI optimization and rigid-flex PCB assembly has opened up exciting possibilities in the development of wearable health monitors. These advanced devices can now offer features such as real-time health monitoring, early symptom detection, and predictive analytics. Moreover, the integration of AI algorithms enables continuous learning and improvement of the device’s performance over time, enhancing its overall functionality.

Future Prospects and Innovations

As technology continues to advance, the future of wearable health monitors looks promising. The integration of AI-optimized rigid-flex PCB assembly is expected to drive further innovations in the field, leading to the development of more intelligent and user-centric devices. With ongoing research and development efforts focusing on enhancing the performance and capabilities of these monitors, we can expect to see even more sophisticated and reliable solutions in the near future.

Conclusion

In conclusion, AI-optimized rigid-flex PCB assembly represents a paradigm shift in the design and development of next-generation wearable health monitors. By leveraging the power of AI algorithms and innovative PCB technologies, these devices can deliver unparalleled performance, accuracy, and user experience. As the demand for advanced health monitoring solutions continues to grow, the integration of AI-optimized rigid-flex PCB assembly will play a crucial role in shaping the future of wearable technology.