In the fast-evolving landscape of healthcare technology, precision rigid-flex assemblies have emerged as a critical component in the development of cutting-edge medical Internet of Things (IoT) implants and diagnostics.

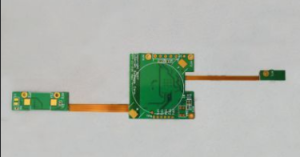

These advanced assemblies offer a unique combination of flexibility and rigidity, making them ideal for use in medical devices that require intricate designs, miniaturization, and reliable performance. From implantable sensors to diagnostic tools, precision rigid-flex assemblies play a pivotal role in enhancing the accuracy, efficiency, and safety of medical devices in the era of IoT.

The Evolution of Medical IoT Technology

The integration of IoT technologies in the medical field has revolutionized the way healthcare is delivered and monitored.

By connecting medical devices to the internet, healthcare professionals can remotely monitor patient health, collect real-time data, and streamline diagnostic processes.

IoT-enabled medical implants and diagnostics have the potential to enhance patient care, improve treatment outcomes, and contribute to the advancement of personalized medicine.

Benefits of Precision Rigid-Flex Assemblies

Precision rigid-flex assemblies are designed to meet the stringent requirements of medical IoT devices.

These assemblies offer a high level of design flexibility, allowing manufacturers to create complex, space-saving designs that are essential for implantable devices and diagnostic tools.

The rigidity of the assemblies ensures structural integrity and reliable performance, while the flexibility enables them to conform to the shape and size constraints of medical devices.

Applications in Medical IoT Implants

One of the key applications of precision rigid-flex assemblies is in the development of implantable medical devices.

These assemblies are used to create miniaturized sensors, electrodes, and other components that can be implanted in the body to monitor vital signs, deliver therapies, or collect diagnostic data.

By leveraging precision rigid-flex assemblies, medical device manufacturers can design implantable devices that are lightweight, durable, and capable of withstanding the rigors of the human body.

Enhancing Diagnostics with Precision Rigid-Flex Assemblies

In addition to implantable devices, precision rigid-flex assemblies are also integral to the development of advanced diagnostic tools.

Medical IoT diagnostics rely on precise sensing mechanisms and data transmission capabilities to provide accurate results in real time.

The flexibility of rigid-flex assemblies allows for the integration of multiple sensors and components in a compact form factor, enabling healthcare professionals to perform diagnostics efficiently and with high accuracy.

Challenges and Considerations

While precision rigid-flex assemblies offer numerous benefits for medical IoT devices, there are challenges that manufacturers must address.

Ensuring the biocompatibility of materials used in the assemblies, maintaining reliability over the device’s lifespan,

and meeting regulatory requirements are critical considerations in the design and production of medical IoT implants and diagnostics.

Collaborating with experienced partners and adhering to industry standards can help overcome these challenges and ensure the successful integration of precision rigid-flex assemblies in medical devices.

Conclusion

Precision rigid-flex assemblies represent a pivotal technology in the development of innovative medical IoT implants and diagnostics.

By offering a unique combination of flexibility and rigidity, these assemblies enable medical device manufacturers to create sophisticated, reliable, and compact devices that enhance patient care and diagnostic accuracy.

As the healthcare industry continues to embrace IoT technologies, the role of precision rigid-flex assemblies will only grow in importance, shaping the future of medical devices and diagnostics.