In today’s rapidly evolving tech landscape, the demand for cost-effective and reliable electronic components is higher than ever.

For companies producing mass-market IoT products, finding efficient assembly strategies for rigid-flex PCBs is crucial.

These innovative circuit boards offer the benefits of both rigid and flexible boards, making them ideal for applications requiring space-saving design and enhanced durability.

In this article, we will delve into cost-effective rigid-flex PCB assembly strategies tailored for mass-market IoT products, highlighting key factors to consider in optimizing production processes and cost-efficiency.

Understanding Rigid-Flex PCBs in IoT Products

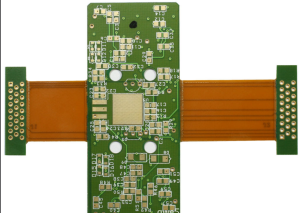

Rigid-flex PCBs combine the best features of rigid and flexible circuits, offering a versatile solution for IoT devices that require compact designs and reliable performance.

These specialized boards consist of both rigid sections that provide structural stability and flexible sections that enable bending or folding.

The seamless integration of rigid and flexible elements in a single board reduces the need for additional connectors and simplifies the overall assembly process.

As such, rigid-flex PCBs are becoming increasingly popular in IoT applications where space constraints and durability are paramount.

Cost-Effective Component Selection for Rigid-Flex PCB Assembly

When aiming to optimize production costs for mass-market IoT products, careful consideration of component selection is essential.

Choosing components that are readily available, cost-effective, and compatible with the manufacturing process can significantly impact the overall assembly expenses.

Working closely with component suppliers to leverage bulk purchasing discounts and sourcing standard components can help reduce material costs without compromising quality or performance.

Additionally, standardized component sizes and configurations can streamline the assembly process and minimize the risk of errors during production.

Design for Manufacturing (DFM) Principles for Cost Efficiency

Implementing Design for Manufacturing (DFM) principles early in the product development phase can lead to substantial cost savings in rigid-flex PCB assembly.

By designing PCB layouts that optimize material usage, reduce waste, and simplify assembly steps, manufacturers can enhance efficiency and lower production costs.

Minimizing the number of layers in the PCB stack-up, using standard board sizes, and optimizing component placement for automated assembly are effective DFM strategies for cost-effective rigid-flex PCB production. Collaborating with experienced PCB designers and manufacturers to adhere to DFM guidelines can help mitigate potential production challenges and ensure a smooth assembly process.

Streamlining Assembly Processes with Automation

Automation plays a key role in streamlining rigid-flex PCB assembly processes and improving cost-efficiency for mass-market IoT products.

Leveraging automated equipment for tasks such as component placement, soldering, and testing can significantly reduce labor costs and enhance production speed.

Automated assembly aligns components with precision, minimizes human error, and ensures consistent quality across batches.

By investing in state-of-the-art assembly equipment and leveraging advanced automation technologies, manufacturers can achieve higher productivity rates,

lower defect rates, and ultimately drive down production costs for rigid-flex PCBs used in IoT applications.

Conclusion

Cost-effective rigid-flex PCB assembly strategies are essential for companies looking to optimize production processes and deliver high-quality IoT products to the mass market.

By focusing on component selection, Design for Manufacturing principles, and automation, manufacturers can achieve significant cost savings while maintaining product quality and performance standards.

Embracing the versatility and efficiency of rigid-flex PCBs, coupled with strategic cost optimization strategies, can propel mass-market IoT products to new heights of innovation and market competitiveness.