In the constantly evolving world of smart devices, the quest for innovation and miniaturization has led to the development of Flex-Rigid PCB transition techniques that serve to eliminate connectors, thereby enhancing the reliability and performance of these devices. As technology advances and devices become more compact, traditional connectors are no longer the most efficient solution.

By seamlessly integrating flexible and rigid PCBs, manufacturers can create devices that are not only smaller but also more durable and cost-effective.

In this article, we will explore how Flex-Rigid PCB transition techniques are revolutionizing the industry and reshaping the landscape of smart devices.

The Evolution of Flex-Rigid PCB Transition Techniques

Flex-Rigid PCB transition techniques represent a significant advancement in the field of electronics manufacturing.

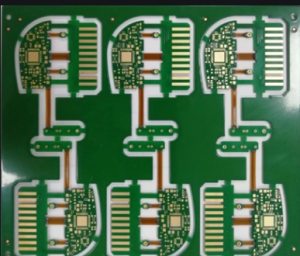

By combining flexible PCBs, which are known for their ability to bend and twist, with rigid PCBs that provide structural support and stability, manufacturers can overcome the limitations of traditional connectors.

These transition techniques involve the use of specialized materials and processes to seamlessly join the flexible and rigid sections, creating a single, integrated board that offers the best of both worlds.

Benefits of Eliminating Connectors in Smart Devices

One of the primary benefits of utilizing Flex-Rigid PCB transition techniques is the elimination of connectors in smart devices.

Connectors are often the weakest link in electronic devices, susceptible to wear and tear, corrosion, and mechanical failure.

By removing connectors and integrating Flex-Rigid PCBs, manufacturers can improve the overall reliability and longevity of smart devices.

This not only reduces the risk of connectivity issues but also enhances the device’s resistance to environmental factors such as moisture and temperature variations.

Enhanced Design Flexibility and Space Optimization

Another advantage of Flex-Rigid PCB transition techniques is the enhanced design flexibility they provide.

By eliminating connectors, manufacturers have more freedom to design compact and sleek devices that meet the demands of modern consumers.

The integration of Flex-Rigid PCBs allows for more efficient use of space within the device, enabling the placement of components in optimal configurations.

This not only improves the aesthetics and ergonomics of the device but also enhances its functionality and performance.

Improved Signal Integrity and Electrical Performance

Flex-Rigid PCB transition techniques also contribute to improved signal integrity and electrical performance in smart devices.

Traditional connectors introduce impedance and signal loss, which can degrade the quality of electrical signals and impact the overall performance of the device.

By transitioning to Flex-Rigid PCBs, manufacturers can minimize signal distortion and improve signal transmission efficiency.

This results in better connectivity, reduced electromagnetic interference, and overall enhanced electrical performance.

Cost and Time Savings in Manufacturing

In addition to the technical advantages, the adoption of Flex-Rigid PCB transition techniques can lead to cost and time savings in the manufacturing process.

By eliminating connectors, manufacturers reduce the number of components, assembly steps, and potential points of failure in the device.

This streamlines the manufacturing process, reduces production costs, and accelerates time-to-market.

Furthermore, the longevity and reliability of devices produced using Flex-Rigid PCBs can lead to lower maintenance and replacement costs for consumers, enhancing the overall value proposition.

Conclusion

In conclusion, Flex-Rigid PCB transition techniques are a game-changer in the realm of smart devices, offering a host of benefits that go beyond mere miniaturization.

By eliminating connectors and seamlessly integrating flexible and rigid PCBs, manufacturers can create devices that are more reliable, durable, and compact.

The enhanced design flexibility, improved signal integrity, and cost efficiencies afforded by Flex-Rigid PCB transition techniques are reshaping the landscape of smart devices and driving innovation in the electronics industry.

As the demand for smaller, smarter, and more sophisticated devices continues to grow, the adoption of Flex-Rigid PCB transition techniques is poised to play a pivotal role in meeting these demands and propelling the industry forward into a new era of connectivity and functionality.