Thermal Management Solutions in Rigid-Flex Assemblies for High-Power Smart Home Devices

Thermal management solutions in rigid-flex assemblies are becoming increasingly crucial in the realm of high-power smart home devices.

As the demand for smart technology surges, so does the need for efficient heat dissipation to maintain device performance and longevity.

This article delves into the innovative thermal management techniques employed in rigid-flex assemblies and explores their significance in today’s smart home ecosystem.

The Need for Effective Thermal Management

The adoption of high-power smart home devices, such as advanced lighting systems, smart HVAC units, and powerful security cameras, poses challenges primarily due to heat generation.

Electronic components, especially those operating at high frequencies, can generate substantial thermal output. If not managed correctly, this heat can lead to performance degradation, reliability issues, and ultimately, device failure. Therefore, integrating effective thermal management solutions in rigid-flex assemblies is imperative to address these challenges.

Understanding Rigid-Flex Assemblies

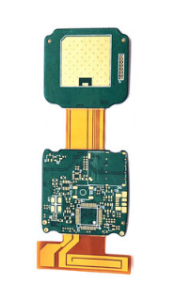

Rigid-flex assemblies combine the benefits of both rigid and flexible printed circuit boards (PCBs).

This technology allows for compact designs and intricate layouts that traditional configurations cannot achieve.

Rigid-flex assemblies are particularly beneficial for smart home devices due to their ability to fit into tight spaces and reduce weight without sacrificing performance.

Advantages of Rigid-Flex Technology

- Space Efficiency: These assemblies allow for intricate designs, enabling the integration of multiple components within a limited area.

- Improved Reliability: The elimination of connectors and solder joints reduces points of failure, enhancing overall device reliability.

- Weight Reduction: Compared to traditional PCBs, rigid-flex assemblies are lighter, which is crucial for portable and multi-functional devices.

Thermal Management Techniques for Rigid-Flex Assemblies

To ensure optimal performance of high-power smart home devices, several thermal management strategies can be employed within rigid-flex assemblies:

1. Heat Sinks and Spreaders

Heat sinks and spreaders are fundamental components in thermal management.

These devices enhance the surface area available for heat dissipation.

In rigid-flex assemblies, strategically placing heat sinks or using thermal spreaders can significantly enhance heat distribution, thereby keeping critical components within operational temperature ranges.

Selecting materials with high thermal conductivity, such as aluminum or copper, can further boost performance.

2. Thermal Interface Materials (TIMs)

Thermal interface materials facilitate more efficient heat transfer between components and heat sinks.

These materials fill air gaps and microscopic imperfections, improving thermal conductivity.

Utilizing high-performance TIMs tailored for specific assembly configurations can greatly minimize thermal resistance and ensure effective heat management in high-power applications.

3. Active Cooling Solutions

While passive cooling methods—like heat sinks and natural airflow—are effective, high-demand smart home devices may require active cooling solutions.

Incorporating small fans or liquid cooling systems in rigid-flex assemblies may provide the necessary thermal control for devices that generate extreme amounts of heat.

Active systems can maintain optimal operating temperatures, ensuring longevity and reliability.

4. Design Considerations

The design of rigid-flex assemblies plays a pivotal role in thermal management.

Engineers must carefully consider the placement of heat-generating components and how heat will disperse throughout the assembly.

Utilizing simulation software can help predict thermal behavior under various operating conditions, allowing engineers to optimize the layout for better thermal performance.

Future Outlook

As smart home technology evolves, so too do the requirements for effective thermal management solutions in rigid-flex assemblies.

Industries will continue to innovate, exploring new materials and designs that offer improved thermal conductivity and efficiency.

Implementing advanced technologies like embedded sensors for real-time thermal monitoring can also lead to proactive thermal management strategies.

Conclusion

Thermal management solutions in rigid-flex assemblies are paramount for ensuring the reliability and performance of high-power smart home devices.

As consumer demand for smart technology increases, the importance of integrating advanced thermal management strategies becomes undeniable.

By adopting innovative approaches, companies can enhance product performance, extend lifespan, and meet the growing expectations of today’s technology-driven consumers.

The future of smart home devices relies heavily on the ability to manage heat, making effective thermal solutions an essential area of focus for development in the industry.