Next-Gen Rigid-Flex PCB Fabrication: Integrating AI for Yield Optimization and Precision

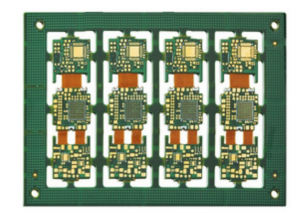

Next-gen rigid-flex PCB fabrication is revolutionizing the electronics industry, combining the best of rigid and flexible printed circuit boards (PCBs).

This innovation allows for intricate designs, lighter products, and greater reliability in demanding applications.

However, as the complexity of these boards increases, so too do challenges related to manufacturing yield and precision.

By integrating artificial intelligence (AI) into the fabrication process, manufacturers can achieve unprecedented levels of optimization, ultimately enhancing product quality and reliability.

Understanding Rigid-Flex PCBs

Rigid-flex PCBs are hybrid circuit boards that integrate both rigid and flexible substrates.

This design enables manufacturers to create compact and efficient devices, which are crucial in fields such as aerospace, medical devices, and consumer electronics.

The combination allows for the design of boards that can bend and flex, reducing the overall size of the device while maintaining the necessary functionality.

Despite their advantages, the fabrication of rigid-flex PCBs presents unique challenges, particularly regarding precision and yield.

The intricacies of layering multiple materials and ensuring proper connections between the rigid and flexible sections require meticulous attention to detail.

As a result, integrating advanced technologies such as AI has become paramount in achieving optimal results in this complex manufacturing environment.

The Role of AI in PCB Fabrication

AI is transforming the landscape of manufacturing across various industries, and PCB fabrication is no exception.

With the ability to analyze vast amounts of data and identify patterns, AI can assist in several critical areas:

1. Yield Optimization

One of the most significant benefits of AI in rigid-flex PCB fabrication is its impact on yield optimization.

Yield, which refers to the percentage of functional boards produced as a proportion of total boards manufactured, is a crucial metric in electronics manufacturing.

High yield rates mean reduced costs and greater efficiency.

By utilizing machine learning algorithms, manufacturers can analyze historical production data to identify factors that lead to defects.

AI can predict potential failure points and suggest modifications to the fabrication process.

For instance, by analyzing thermal profiles and material properties, AI systems can provide recommendations on optimal processing conditions that maximize yield.

2. Precision and Quality Control

Precision is paramount in rigid-flex PCB fabrication, where even minor deviations can lead to functional failures.

AI technologies can enhance quality control processes by employing computer vision and predictive analytics.

With advanced imaging techniques, AI can inspect PCBs for defects that are not easily visible to the human eye.

This technology allows for real-time monitoring during production, identifying issues such as misalignments, incomplete soldering, or material irregularities.

As a result, manufacturers can address these issues promptly, ensuring that only high-quality boards progress through the production line.

Advancements in Design and Simulation

The integration of AI extends beyond the manufacturing process itself; it also enhances the design and simulation stages of rigid-flex PCB development.

Traditionally, PCB designers relied on static simulations to predict how a board would perform after fabrication.

AI-driven tools now allow for dynamic simulations that provide insights into the electrical performance and mechanical integrity of a design under various conditions.

These tools can suggest alternative design iterations that optimize space while maintaining functionality.

By enabling designers to visualize the impact of their choices more effectively, AI can help create boards that not only meet specifications but also push the boundaries of what rigid-flex technology can accomplish.

Benefits of AI-Driven Rigid-Flex PCB Fabrication

The integration of AI into rigid-flex PCB fabrication yields numerous benefits, including:

- Reduced Production Costs: By enhancing yield and identifying defects early, manufacturers can significantly lower material costs and labor.

- Faster Time to Market: AI-driven automation can streamline the production process, facilitating rapid prototyping and reducing lead times.

- Enhanced Product Reliability: With improved precision and quality control, end products are more likely to meet performance expectations, leading to greater customer satisfaction.

Conclusion

As the demand for increasingly complex and reliable electronic devices grows, next-gen rigid-flex PCB fabrication represents a crucial innovation in the electronics industry.

By harnessing the power of AI for yield optimization and precision, manufacturers can overcome traditional challenges and set new standards for quality and performance.

This integration not only enhances current fabrication processes but also lays the groundwork for future advancements in PCB technology.

Embracing AI is not just an option in today’s competitive landscape; it’s a necessity for leading manufacturers aiming to push the envelope of what’s possible in rigid-flex design and production.