Case Study: Reducing Rigid-Flex PCB Design Costs in High-Volume Production

Rigid-flex PCB design costs can significantly impact manufacturers aiming to produce high-quality electronics at scale.

With the persistent demand for lightweight, compact, and high-performance devices, understanding how to effectively reduce the associated costs of rigid-flex technology is crucial for both new and established companies.

This case study explores strategies implemented by a leading electronics manufacturer to optimize design processes, minimize waste, and lower the overall cost of rigid-flex PCBs in high-volume production.

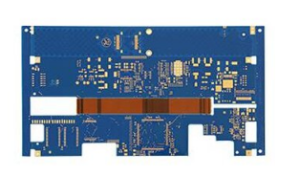

Understanding Rigid-Flex PCBs

Before diving into the cost-reduction strategies, it’s essential to grasp what rigid-flex PCBs are.

These boards combine the benefits of both rigid and flexible circuit boards, allowing for complex designs and adaptable configurations.

Their unique properties make them ideal for applications in industries such as aerospace, medical devices, and consumer electronics, where space optimization and reliability are paramount.

However, the benefits come with heightened production costs, largely due to the intricate design and manufacturing processes involved.

As companies aim to scale up their production, finding ways to reduce these costs while maintaining quality becomes imperative.

Challenges in Rigid-Flex PCB Production

The primary challenges in producing rigid-flex PCBs include:

- Complex Design Requirements: Rigid-flex designs often incorporate various layers and materials that can complicate the manufacturing process.

- Material Costs: The high-quality materials necessary for rigid-flex boards are more expensive than standard PCB materials.

- Longer Production Times: The fabrication process for rigid-flex PCBs is often longer, leading to increased labor costs and delays.

Addressing these challenges requires a multifaceted approach that takes into account design efficiency, material selection, and manufacturing practices.

Strategies for Cost Reduction

To tackle the high costs associated with rigid-flex PCB design, the manufacturer adopted several key strategies:

1. Design for Manufacturability (DFM) Principles

Implementing DFM principles early in the design process can streamline production.

The team conducted workshops involving engineers and manufacturers to identify potential design flaws before fabrication.

This collaborative approach ensured designs were optimized for assembly, thereby reducing rework and material waste.

2. Material Optimization

To reduce material costs without compromising quality, the manufacturer explored alternative suppliers and materials.

By analyzing various available options, they identified cost-effective materials that still met industry standards.

They also negotiated bulk purchasing agreements, further decreasing costs through economies of scale.

3. Advanced Simulation Tools

Utilizing advanced simulation tools allowed the company to create virtual prototypes before actual production.

These tools helped to identify potential issues early in the design phase and reduced the need for costly iterations, ultimately saving both time and resources.

4. Lean Manufacturing Techniques

The adoption of lean manufacturing principles was critical. By analyzing production workflows, the team identified bottlenecks and inefficiencies.

They implemented practices such as just-in-time supply chain management to minimize inventory costs and reduce waste, ensuring smoother production processes.

5. Strategic Partnerships

Forming strategic partnerships with key suppliers and manufacturers provided the company with valuable insights into best practices and innovative techniques.

These collaborations not only offered learning opportunities but also improved the overall supply chain, allowing for more efficient material sourcing and production processes.

Results of Implementing Strategies

The results of these strategies were significant.

Within six months of implementation, the manufacturer achieved a 20% reduction in rigid-flex PCB design costs.

By streamlining design processes and optimizing material use, they also improved overall production efficiency and reduced lead times.

Moreover, the enhanced collaboration with suppliers led to better pricing agreements, resulting in a sustainable cost-saving model that could be replicated for future projects.

The improved designs and processes also enhanced product quality, leading to higher customer satisfaction rates.

Conclusion

Reducing rigid-flex PCB design costs in high-volume production is a complex but attainable goal.

By incorporating design for manufacturability principles, optimizing materials, utilizing advanced tools, applying lean techniques, and fostering strategic partnerships, manufacturers can achieve substantial savings.

As the demand for compact and efficient electronic devices continues to grow, the insights gained from this case study will serve as a valuable guide for companies looking to stay competitive in a rapidly evolving market.