Best Practices for Rigid-Flex PCB Design: A Comprehensive Guide

Best practices for rigid-flex PCB design are essential for engineers and designers looking to create reliable, efficient, and high-performance electronics.

As technology continues to evolve, the demand for compact and flexible circuit board solutions has increased.

Rigid-flex PCBs combine the best features of both rigid and flexible PCBs, making them ideal for applications in various industries, including aerospace, medical devices, and consumer electronics.

This article outlines key considerations and best practices to ensure successful rigid-flex PCB design.

Understanding Rigid-Flex PCBs

Before delving into the best practices for design, it’s crucial to understand what rigid-flex PCBs are.

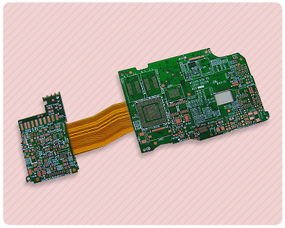

These circuit boards consist of both rigid sections and flexible sections, allowing them to operate effectively in confined spaces.

Rigid-flex designs can reduce the number of interconnects and connectors needed, leading to a decrease in overall size and weight while enhancing reliability.

Key Considerations in Initial Design

When embarking on rigid-flex PCB design, starting with a clear understanding of the project requirements is vital.

Designers should consider the following aspects:

1. Applications and Environment

Consider the intended use of the PCB. Different applications require varying levels of durability, flexibility, and thermal resistance.

For instance, PCBs used in aerospace must withstand extreme temperatures and vibrations, while those in consumer electronics may prioritize cost-effectiveness and aesthetics.

2. Layer Count

The layer count directly influences the complexity and cost of the rigid-flex PCB.

A higher layer count can offer more routing options and functionality but may also complicate the design and increase production costs.

A balanced approach is to find the minimum layer count necessary to meet performance specifications.

Best Practices for Design

With an understanding of the core principles, we can now delve deeper into practical best practices for effective rigid-flex PCB design.

CAD Tools and Design Software

Utilizing the right computer-aided design (CAD) tools is fundamental.

Seek out software that specifically accommodates rigid-flex designs, providing features tailored for layering, routing, and flexible areas.

For instance, tools that allow 3D visualization can help identify conflict areas before moving to production.

1. Optimize Layer Stack-Up

Creating an optimal layer stack-up is one of the cornerstones of rigid-flex PCB design.

The stack-up should support the mechanical and electrical requirements of the design.

Consider using controlled impedance layers for signal integrity and proper dielectric materials to support bending and stretching in flexible areas.

2. Design for Flexibility

Flexible sections should be designed with individual traces spaced adequately apart to avoid stress points.

Avoid sharp corners or bends, as these can lead to fatigue and eventual failure through repeated movement.

Incorporate Test Points

Incorporating test points during the design phase can significantly ease future debugging and testing processes.

Strategically placed test pads within rigid and flexible areas ensure easy access without compromising the design integrity.

This consideration saves time during troubleshooting and can reduce costs in the long run.

Simulation and Prototyping

Before finalizing the design, thorough testing through simulation and prototyping is crucial.

Software simulations can help assess electrical performance, thermal behavior, and mechanical constraints.

Once simulations confirm the viability of the design, create prototypes to evaluate the physical characteristics and overall performance in real-world conditions.

Consider Manufacturing Capabilities

Collaboration with manufacturers during the design process ensures that the design intentions align with available fabrication technologies.

Engage manufacturers early to discuss tooling requirements, material options, and assembly processes.

This involvement helps avoid common pitfalls during the transition from design to production.

Document Everything

Finally, documentation is key to successful rigid-flex PCB design.

Ensure to maintain comprehensive records that include design iterations, specifications, and manufacturing notes.

Detailed documentation not only facilitates clear communication among team members but is also invaluable for future revisions and troubleshooting.

Conclusion

Incorporating these best practices for rigid-flex PCB design can significantly enhance the efficiency, reliability, and performance of electronic devices.

Whether you are designing for cutting-edge technology in aerospace or creating user-friendly consumer products, understanding the intricacies of rigid-flex PCBs is crucial.

By carefully considering design criteria, collaborating with manufacturers, and utilizing proper visualization tools, engineers can create innovative solutions that meet the challenging demands of modern applications.

With the right approach, rigid-flex PCBs can lead the way in compact and flexible electronic designs that push the boundaries of what’s possible.