Essential Rigid-Flex PCB Design Guidelines for Optimal Performance

Essential rigid-flex PCB design guidelines are crucial for engineers and designers who aim to create high-performance electronic devices.

As technology continues to evolve, the demand for compact, durable, and efficient circuit boards has risen significantly.

Rigid-flex PCBs combine the advantages of rigid and flexible circuits, offering versatility in design and enhanced functionality.

To achieve optimal performance, several critical factors must be considered during the design phase.

Understanding Rigid-Flex PCB Basics

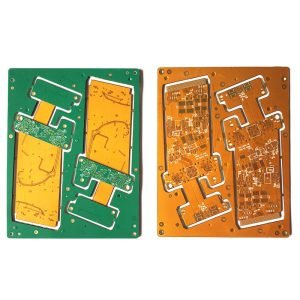

Rigid-flex PCBs are a hybrid of rigid and flexible circuit boards, allowing for innovative designs that can adapt to various mechanical and thermal constraints.

This dual functionality makes them an excellent choice for applications in aerospace, medical devices, consumer electronics, and automotive technology.

The capability to fit in tight spaces without compromising performance is one of the greatest advantages of rigid-flex designs.

Key Components of Rigid-Flex Design

- Layer Structure

The foundational element of any PCB is its layer structure.

In a rigid-flex design, the layers are often made from multiple materials, including a combination of rigid substrates and flexible materials.

Common combinations may involve rigid FR4 alongside flexible polyimide.

Understanding how to layer these materials effectively is essential to achieving both mechanical stability and electrical performance. - Trace Routing

Proper trace routing is vital in rigid-flex PCBs to prevent issues like signal integrity loss and electromagnetic interference (EMI).

Engineers should aim for smooth traces with gentle bends, especially in the flexible areas.

Avoiding sharp corners and unnecessary via transitions will enhance the board’s reliability and performance. - Via Types and Placement

Vias, the conductive pathways that connect different layers, are crucial in rigid-flex design.

Blind and buried vias are often used to minimize space and achieve a more compact layout.

High-density interconnect (HDI) technology can also be beneficial, allowing for smaller vias with better performance.

The placement of vias should be strategic to ensure they do not compromise the integrity of the flexible sections.

Essential Design Considerations

- Mechanical Stress Management

Mechanical stress is a common concern in flexible circuits due to their ability to bend and flex.

Understanding the areas that will experience the most stress will help designers create features such as stress-relief zones or specific geometrical designs that can withstand repeated bending. - Thermal Management

Variations in temperature can affect the performance of PCBs.

Designers should consider thermal expansion properties of both rigid and flexible materials.

Utilizing thermal relief pads and appropriate thermal vias can aid in dissipating heat effectively and preventing potential failures. - Impedance Control

Maintaining controlled impedance throughout the PCB is vital for high-speed applications.

Variations in dielectric material thickness and trace width can affect impedance, so calculations should be performed upfront during the design phase.

Additionally, using suitable termination methods can help manage reflections and enhance signal integrity.

Validation and Testing

Before full-scale production, it is essential to validate and test the rigid-flex PCB design.

Functional testing, thermal cycling, and mechanical durability tests are necessary to ensure that the board will perform as expected under various operational conditions.

Prototyping offers an opportunity to observe the performance of the design in real-world conditions, allowing for further refinement.

DFM and DFT Practices

Incorporating Design for Manufacturability (DFM) and Design for Testability (DFT) practices can significantly impact the overall success of the project.

DFM encourages designs that are easy to produce, reducing manufacturing costs and time.

DFT ensures that testing can be performed efficiently, helping to identify issues early in the production process.

Conclusion

Implementing essential rigid-flex PCB design guidelines is vital for achieving optimal performance in electronic devices.

By understanding fundamental concepts, considering mechanical and thermal factors, and validating designs thoroughly, engineers can create reliable and high-performing rigid-flex circuits.

As the demand for innovative electronic solutions continues to grow, mastering these guidelines will be essential for staying competitive in the electronics industry.

Embracing this complexity while adhering to best practices can lead to exciting advancements that push the boundaries of technology.