What Makes Rigid-Flex PCBs More Expensive?

Rigid-flex PCBs, or printed circuit boards, have become increasingly popular in the electronics industry due to their flexibility and durability.

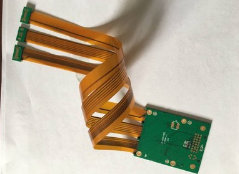

These boards are a combination of rigid and flexible materials, allowing for more complex designs and improved performance in electronic devices.

While the benefits of using rigid-flex PCBs are numerous, they do come at a higher cost compared to traditional rigid PCBs.

In this article, we will explore the reasons why rigid-flex PCBs are more expensive and why the investment is worth it for many electronic device manufacturers.

One of the main reasons why rigid-flex PCBs are more expensive is the complexity of the manufacturing process.

Unlike traditional rigid PCBs, which are made from a single layer of rigid material, rigid-flex PCBs require multiple layers of both rigid and flexible materials.

This adds complexity to the manufacturing process, as each layer must be carefully aligned and bonded together to create a seamless and reliable circuit board.

Additionally, the materials used in rigid-flex PCBs are often more expensive than those used in traditional rigid PCBs, further driving up the cost of production.

Another factor that contributes to the higher cost of rigid-flex PCBs is the specialized equipment and expertise required for their manufacture.

Rigid-flex PCBs are more challenging to design and fabricate than traditional rigid PCBs, requiring specialized equipment and skilled technicians to ensure that the boards meet the necessary quality standards.

This specialized equipment and expertise come at a higher cost, which is ultimately passed on to the consumer in the form of higher prices for rigid-flex PCBs.

Despite the higher cost of rigid-flex PCBs, many electronic device manufacturers are willing to invest in these boards due to the numerous benefits they offer.

One of the main advantages of using rigid-flex PCBs is their flexibility, which allows for more compact and lightweight designs in electronic devices.

This flexibility also makes rigid-flex PCBs more durable and resistant to damage from bending and twisting, making them ideal for use in devices that are subject to frequent movement or vibration.

In addition to their flexibility, rigid-flex PCBs offer improved reliability and performance compared to traditional rigid PCBs.

The multiple layers of rigid and flexible materials in rigid-flex PCBs allow for more complex circuit designs, resulting in better signal integrity and reduced electromagnetic interference.

This leads to improved performance and efficiency in electronic devices, making rigid-flex PCBs a popular choice for manufacturers looking to enhance the quality of their products.

Furthermore, the compact size and lightweight nature of rigid-flex PCBs can also lead to cost savings in the long run.

By using rigid-flex PCBs, manufacturers can reduce the overall size and weight of their electronic devices, resulting in lower shipping and storage costs.

Additionally, the improved reliability and performance of rigid-flex PCBs can help to reduce the need for repairs and replacements, saving manufacturers money on maintenance and downtime.

In conclusion, while rigid-flex PCBs may be more expensive than traditional rigid PCBs, the benefits they offer make them a worthwhile investment for many electronic device manufacturers.

The flexibility, durability, reliability, and performance of rigid-flex PCBs make them an ideal choice for a wide range of applications, from consumer electronics to aerospace and medical devices.

By understanding the reasons behind the higher cost of rigid-flex PCBs and the benefits they provide, manufacturers can make informed decisions about incorporating these advanced circuit boards into their products.