Accelerated Life Testing for Rigid-Flex PCBs

Advanced Testing Methods for Rigid-Flex PCB Durability

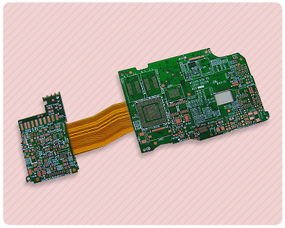

Rigid-flex PCBs are becoming increasingly popular in the electronics industry due to their ability to provide a compact and lightweight solution for complex electronic devices.

However, ensuring the durability and reliability of these boards is crucial to their performance in the field.

Advanced testing methods, such as accelerated life testing, are essential for evaluating the durability of rigid-flex PCBs and identifying potential failure modes.

Accelerated life testing is a method used to simulate the long-term effects of aging on electronic components and systems in a shorter period of time.

By subjecting rigid-flex PCBs to accelerated stress conditions, such as temperature cycling, vibration, and humidity, engineers can assess the board’s performance under extreme conditions and predict its lifespan in the field.

One of the key benefits of accelerated life testing is its ability to identify potential failure modes that may not be apparent during normal operation.

By subjecting rigid-flex PCBs to accelerated stress conditions, engineers can induce failures in the board and analyze the root causes of these failures.

This information can then be used to improve the design and manufacturing process of the PCB, ultimately leading to a more reliable and durable product.

In addition to identifying potential failure modes, accelerated life testing can also help engineers determine the optimal operating conditions for rigid-flex PCBs.

By subjecting the boards to a range of stress conditions, engineers can identify the limits of the board’s performance and establish guidelines for safe operation.

This information is crucial for ensuring the reliability of the PCB in real-world applications and preventing premature failures.

One of the challenges of accelerated life testing for rigid-flex PCBs is the complexity of the testing process.

Unlike traditional PCBs, rigid-flex boards consist of both rigid and flexible components, which can make it difficult to accurately simulate the stress conditions that the board will experience in the field.

To overcome this challenge, engineers must carefully design the test setup and select appropriate stress conditions that accurately reflect the board’s operating environment.

Another challenge of accelerated life testing for rigid-flex PCBs is the limited availability of standardized test methods.

Unlike traditional PCBs, which have well-established test standards, rigid-flex boards are relatively new and lack standardized testing procedures.

As a result, engineers must develop custom test methods for evaluating the durability of rigid-flex PCBs, which can be time-consuming and costly.

Despite these challenges, accelerated life testing remains a valuable tool for evaluating the durability of rigid-flex PCBs.

By subjecting the boards to accelerated stress conditions, engineers can identify potential failure modes, determine optimal operating conditions, and improve the reliability of the PCB.

As the demand for compact and lightweight electronic devices continues to grow, advanced testing methods such as accelerated life testing will play a crucial role in ensuring the durability and reliability of rigid-flex PCBs.