Advancements in High-Temperature Materials for Aerospace Rigid-Flex Applications

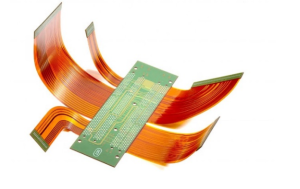

Advancements in high-temperature materials have revolutionized the aerospace industry, particularly in the realm of rigid-flex applications.

These materials are designed to withstand extreme temperatures and harsh conditions, making them ideal for use in aerospace components that are exposed to high levels of heat and stress.

In recent years, researchers and engineers have made significant strides in developing new high-temperature materials that offer improved performance and durability.

One of the key challenges in aerospace engineering is finding materials that can maintain their structural integrity at high temperatures.

Traditional materials such as aluminum and steel have limitations when it comes to withstanding extreme heat, which can lead to component failure and safety risks.

High-temperature materials, on the other hand, are specifically engineered to withstand temperatures well above what traditional materials can handle.

One of the most promising high-temperature materials for aerospace rigid-flex applications is silicon carbide (SiC).

SiC is a ceramic material that offers exceptional thermal conductivity and mechanical strength, making it ideal for use in high-temperature environments.

SiC can withstand temperatures up to 2000°C, far surpassing the capabilities of traditional materials. This makes it an excellent choice for components such as engine parts, exhaust systems, and heat shields.

Another high-temperature material that is gaining popularity in the aerospace industry is carbon fiber reinforced polymer (CFRP).

CFRP is a composite material that combines the strength and stiffness of carbon fiber with the flexibility and durability of a polymer matrix.

This combination of properties makes CFRP an excellent choice for rigid-flex applications in aerospace, where components need to be both lightweight and able to withstand high temperatures.

In addition to SiC and CFRP, researchers are also exploring the use of advanced ceramics such as alumina and zirconia for high-temperature aerospace applications. |

These materials offer excellent thermal stability and mechanical properties, making them well-suited for use in components that are exposed to extreme heat and stress.

By incorporating these advanced ceramics into aerospace designs, engineers can create components that are lighter, stronger, and more durable than ever before.

One of the key advantages of high-temperature materials is their ability to reduce weight and improve fuel efficiency in aerospace applications.

By using materials that can withstand higher temperatures, engineers can design components that are lighter and more streamlined, leading to reduced fuel consumption and lower emissions.

This is particularly important in the aerospace industry, where every kilogram of weight saved can have a significant impact on performance and efficiency.

In conclusion, the development of new high-temperature materials has opened up exciting possibilities for aerospace rigid-flex applications.

These materials offer improved performance, durability, and efficiency, making them essential for the next generation of aerospace components.

As researchers continue to push the boundaries of material science, we can expect to see even more innovative solutions that will revolutionize the aerospace industry.

High-temperature materials are truly the future of aerospace engineering, paving the way for safer, more efficient, and more advanced aircraft designs.