Benefits of Flex-Rigid PCBs in Satellite Technology

Satellite technology has revolutionized the way we communicate, navigate, and observe our planet from space.

These sophisticated machines orbiting the Earth rely on a multitude of components to function effectively, and one crucial element that plays a significant role in their operation is the flex-rigid printed circuit board (PCB).

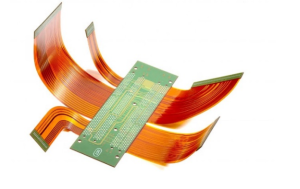

Flex-rigid PCBs are a specialized type of PCB that combines flexible and rigid substrates into a single board, offering a unique set of benefits that make them ideal for use in satellite technology.

One of the key advantages of flex-rigid PCBs in satellite technology is their ability to withstand the harsh conditions of space.

Satellites are exposed to extreme temperatures, radiation, and vibrations, which can put a strain on traditional rigid PCBs.

Flex-rigid PCBs, on the other hand, are designed to be more resilient and durable, making them better suited for the demanding environment of space.

Their flexible substrates allow them to bend and twist without breaking, while their rigid sections provide stability and support for critical components.

In addition to their durability, flex-rigid PCBs offer a high level of design flexibility, allowing engineers to create complex and compact layouts that maximize space efficiency.

This is particularly important in satellite technology, where every square inch of real estate is precious.

By using flex-rigid PCBs, designers can pack more functionality into a smaller footprint, reducing the overall size and weight of the satellite while maintaining performance and reliability.

Furthermore, flex-rigid PCBs help to minimize signal interference and improve signal integrity in satellite systems.

The flexible sections of the PCB can be used to route high-speed signals away from sensitive components, reducing the risk of electromagnetic interference and signal degradation.

This is crucial in satellite technology, where reliable communication and data transmission are essential for mission success.

By using flex-rigid PCBs, engineers can ensure that signals remain clean and stable, even in the harsh electromagnetic environment of space.

Another benefit of flex-rigid PCBs in satellite technology is their cost-effectiveness.

While the initial manufacturing cost of flex-rigid PCBs may be higher than that of traditional rigid PCBs, their long-term benefits far outweigh the upfront investment.

Flex-rigid PCBs have a longer lifespan and require less maintenance than rigid PCBs, reducing the overall cost of ownership over the lifetime of the satellite.

Additionally, their compact design and improved signal integrity can lead to higher performance and efficiency, further enhancing the value proposition of flex-rigid PCBs in satellite technology.

In conclusion, flex-rigid PCBs play a critical role in the success of satellite technology by providing durability, design flexibility, signal integrity, and cost-effectiveness.

These specialized PCBs are essential for ensuring the reliable operation of satellites in the harsh environment of space, where performance and reliability are paramount.

As the demand for satellite technology continues to grow, the importance of flex-rigid PCBs in enabling innovative and efficient satellite designs will only increase.

By leveraging the unique benefits of flex-rigid PCBs, engineers can push the boundaries of what is possible in satellite technology and unlock new opportunities for exploration and discovery in space.