Global Market Demand: The increasing demand for smart devices worldwide drives the growth of rigid flex PCB production, leading to advancements in manufacturing technologies.

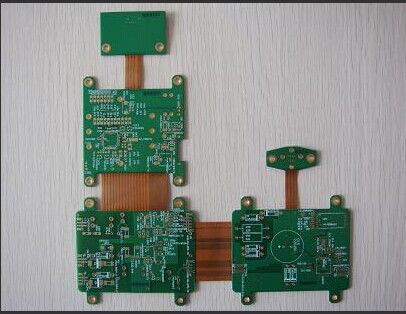

The global demand for smart devices has surged in recent years, driven by the widespread adoption of smartphones, wearables, IoT devices, and other connected technologies. This growing demand has had a profound impact on the electronics manufacturing industry, particularly in the production of rigid-flex printed circuit boards (PCBs). As a critical component in many smart devices, rigid-flex PCBs have seen a significant increase in production, leading to advancements in manufacturing technologies and positioning the industry for continued growth.

One of the primary drivers of rigid-flex PCB production is the proliferation of smartphones and tablets.

These devices require compact, lightweight, and high-performance circuitry to support features such as high-resolution displays, advanced cameras, and 5G connectivity. Rigid-flex PCBs, with their ability to integrate multiple functions into a single board, are ideally suited to meet these demands.

As smartphone manufacturers strive to create sleeker and more powerful devices, the demand for rigid-flex PCBs continues to rise, pushing manufacturers to innovate and scale production.

The wearable technology market is another major contributor to the growth of rigid-flex PCB production.

Devices such as smartwatches, fitness trackers, and medical wearables rely on rigid-flex PCBs to achieve their compact and flexible designs.

These devices must be lightweight, durable, and capable of withstanding constant movement, making rigid-flex PCBs an essential component.

As the wearable market expands, driven by consumer interest in health monitoring and connectivity, the demand for rigid-flex PCBs is expected to grow exponentially.

The Internet of Things (IoT) is also playing a significant role in driving the demand for rigid-flex PCBs. IoT devices, which include smart home appliances, industrial sensors, and connected vehicles, require reliable and efficient circuitry to enable seamless communication and data processing.

Rigid-flex PCBs provide the necessary performance and flexibility to support these applications, making them a key enabler of IoT innovation.

As the number of connected devices continues to grow, the demand for rigid-flex PCBs will only increase.

The automotive industry is another area where rigid-flex PCBs are gaining traction. Modern vehicles are increasingly equipped with advanced electronics, such as infotainment systems, advanced driver-assistance systems (ADAS), and electric vehicle (EV) components.

Rigid-flex PCBs are well-suited to meet the stringent requirements of automotive applications, including durability, thermal management, and resistance to vibrations. As the automotive industry shifts toward electrification and automation, the demand for rigid-flex PCBs is expected to rise significantly.

To meet this growing global demand, manufacturers are investing in advancements in rigid-flex PCB production technologies.

Innovations such as automated assembly, laser drilling, and additive manufacturing are enabling faster, more efficient, and more precise production processes. These advancements not only increase production capacity but also improve the quality and reliability of rigid-flex PCBs, ensuring that they meet the high standards required by modern smart devices.

In conclusion, the increasing global demand for smart devices is driving the growth of rigid-flex PCB production and spurring advancements in manufacturing technologies. As smartphones, wearables, IoT devices, and automotive electronics continue to evolve, rigid-flex PCBs will remain a critical component, enabling innovation and shaping the future of the electronics industry. With ongoing investments in production capabilities, the rigid-flex PCB industry is well-positioned to meet the challenges and opportunities of a connected world.