Reduced Component Count: By integrating multiple functions into a single board, rigid flex PCBs can significantly reduce the component count

In the pursuit of smarter, smaller, and more efficient electronic devices, reducing the number of components is a key objective for engineers and designers. Rigid-flex printed circuit boards (PCBs) have emerged as a powerful solution to this challenge, enabling the integration of multiple functions into a single board. By significantly reducing the component count, rigid-flex PCBs simplify designs, enhance reliability, and lower production costs, making them a preferred choice for modern electronics.

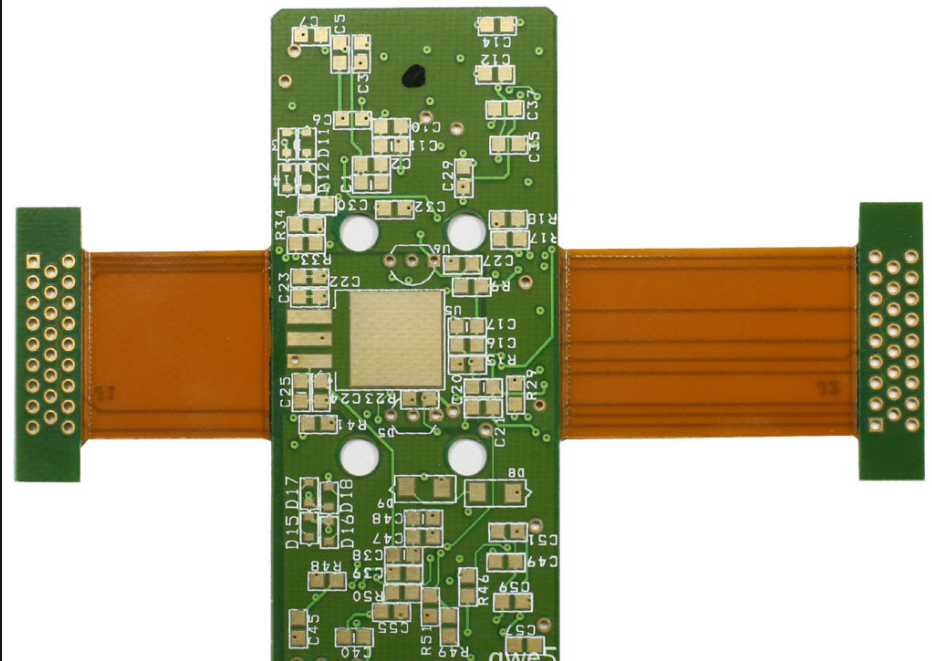

One of the most significant advantages of rigid-flex PCBs is their ability to combine rigid and flexible sections into a unified structure.

This integration eliminates the need for separate connectors, cables, and interconnects, which are often required in traditional PCB designs.

For example, in a smartphone, rigid-flex PCBs can replace multiple rigid boards and their associated connectors, reducing the overall number of components. This not only streamlines the design but also minimizes the risk of failure points, such as loose connections or worn-out cables.

The reduction in component count also leads to a more compact and lightweight design.

In devices like wearables, drones, and medical implants, where space and weight are critical factors, rigid-flex PCBs enable engineers to pack more functionality into a smaller footprint. For instance, a smartwatch that uses rigid-flex PCBs can integrate power management, sensors, and communication modules into a single board, eliminating the need for additional wiring and connectors. This results in a sleeker, more ergonomic device that is easier to wear and use.

Another benefit of reducing the component count is improved reliability.

Fewer components mean fewer potential failure points, which translates to a more durable and dependable product. In industries such as automotive and aerospace, where reliability is paramount, rigid-flex PCBs are increasingly being adopted to ensure consistent performance under harsh conditions.

By consolidating multiple functions into a single board, rigid-flex PCBs reduce the likelihood of mechanical failures, such as broken connectors or disconnected cables, which are common in traditional designs.

The streamlined design of rigid-flex PCBs also simplifies the assembly process, reducing labor and production time.

With fewer components to assemble and connect, manufacturers can achieve faster production cycles and lower costs.

This is particularly beneficial in high-volume industries like consumer electronics, where efficiency and cost-effectiveness are critical to staying competitive. Additionally, the reduced complexity of the assembly process minimizes the risk of human error, leading to higher-quality products and fewer defects.

Furthermore, the integration of multiple functions into a single rigid-flex PCB enhances signal integrity and performance.

By reducing the number of interconnects, engineers can minimize signal loss and electromagnetic interference (EMI), ensuring that the device operates at optimal levels. This is especially important in high-speed and high-frequency applications, such as 5G communication devices and advanced computing systems.

In conclusion, rigid-flex PCBs offer a transformative solution for reducing component count in electronic devices.

By integrating multiple functions into a single board, they simplify designs, improve reliability, and lower production costs.

As the demand for compact, efficient, and reliable electronics continues to grow, rigid-flex PCBs will remain a cornerstone of innovation, enabling the development of next-generation devices that meet the evolving needs of consumers and industries alike.