Streamlined Assembly Process: How Rigid-Flex PCBs Enhance Efficiency

In the fast-paced world of electronics manufacturing, efficiency is key to staying competitive.

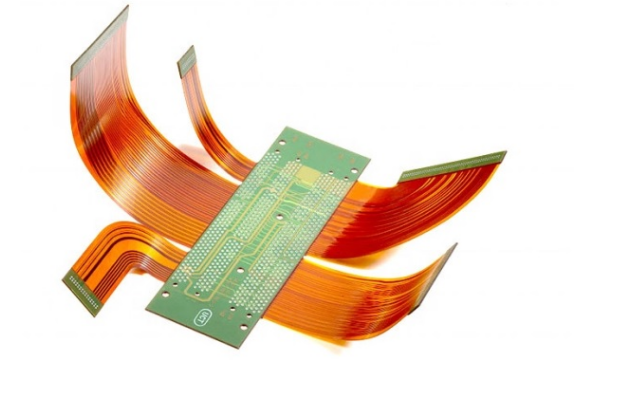

Rigid-flex printed circuit boards (PCBs) have emerged as a powerful tool for streamlining the assembly process, reducing labor, and saving time.

By integrating rigid and flexible sections into a single board, rigid-flex PCBs eliminate many of the challenges associated with traditional PCB assembly, making them an increasingly popular choice for modern electronics.

One of the primary advantages of rigid-flex PCBs is their ability to reduce the number of components and connectors required in a device.

In traditional designs, rigid PCBs are often connected using wires, cables, or connectors, which not only add complexity but also increase the risk of failure due to loose connections or wear and tear. Rigid-flex PCBs, on the other hand, combine rigid and flexible sections into a unified structure, eliminating the need for additional connectors. This simplifies the assembly process and reduces the chances of errors during manufacturing.

The integration of rigid and flexible sections also minimizes the number of assembly steps.

With traditional PCBs, each board must be individually assembled, connected, and tested, which can be time-consuming and labor-intensive.

Rigid-flex PCBs, however, allow multiple functional sections to be manufactured and tested as a single unit.

This not only speeds up the assembly process but also reduces the need for manual intervention, lowering labor costs and improving overall efficiency.

Another benefit of rigid-flex PCBs is their ability to fit into compact and complex designs.

In devices such as smartphones, wearables, and medical equipment, space is often at a premium.

Rigid-flex PCBs can be designed to conform to the shape of the device, reducing the need for additional mounting hardware or enclosures.

This not only simplifies the assembly process but also reduces the overall size and weight of the device, making it more appealing to consumers.

The durability of rigid-flex PCBs further enhances their efficiency in the assembly process.

Traditional PCBs with connectors and cables are more prone to damage during assembly and use, leading to higher rejection rates and increased costs.

Rigid-flex PCBs, with their robust design, are better able to withstand the stresses of assembly and operation, resulting in fewer defects and lower repair costs.

Finally, the use of rigid-flex PCBs can improve the reliability and performance of the final product.

By reducing the number of connections and potential failure points, these PCBs ensure a more stable and consistent performance.

This is particularly important in high-reliability applications such as aerospace, automotive, and medical devices, where even a small failure can have significant consequences.

In conclusion, the streamlined assembly process enabled by rigid-flex PCBs offers numerous benefits, including reduced labor, shorter production times, and improved product reliability. As the demand for smaller, more complex, and more reliable electronics continues to grow, rigid-flex PCBs will play an increasingly important role in driving efficiency and innovation in the electronics manufacturing industry.