Benefits of Using Rigid-Flex PCBs in Diagnostic Equipment

In the world of diagnostic equipment, precision and reliability are paramount. The ability to accurately diagnose medical conditions relies heavily on the quality of the equipment being used.

This is where rigid-flex PCBs come into play, revolutionizing the way diagnostic equipment is designed and manufactured.

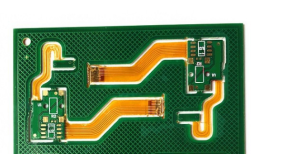

Rigid-flex PCBs offer a unique combination of flexibility and rigidity, making them ideal for use in diagnostic equipment.

The flexibility of these PCBs allows for intricate designs that can be customized to fit the specific needs of the equipment.

This flexibility also allows for the PCB to be bent or folded, making it easier to fit into tight spaces within the equipment.

One of the key benefits of using rigid-flex PCBs in diagnostic equipment is their durability. Traditional PCBs are prone to damage from bending or flexing, which can lead to malfunctions in the equipment.

Rigid-flex PCBs, on the other hand, are designed to withstand repeated bending and flexing without compromising their performance.

This durability ensures that the diagnostic equipment will continue to function reliably over time, reducing the need for costly repairs or replacements.

Another benefit of using rigid-flex PCBs in diagnostic equipment is their compact size. The flexible nature of these PCBs allows for a more compact design, which is essential in medical devices where space is limited.

By using rigid-flex PCBs, manufacturers can create smaller, more portable diagnostic equipment that is easier to transport and use in a variety of settings.

In addition to their durability and compact size, rigid-flex PCBs also offer improved signal integrity.

The flexible nature of these PCBs reduces the risk of signal interference, ensuring that the diagnostic equipment can accurately and reliably transmit data.

This is crucial in medical settings where accurate data is essential for making informed decisions about patient care.

Furthermore, rigid-flex PCBs are also more cost-effective than traditional PCBs. While the initial cost of manufacturing rigid-flex PCBs may be higher, the long-term savings are significant.

The durability of these PCBs means that they are less likely to require repairs or replacements, saving manufacturers money in the long run.

Additionally, the compact size of rigid-flex PCBs reduces the overall cost of the diagnostic equipment, making it more affordable for healthcare providers.

Overall, the benefits of using rigid-flex PCBs in diagnostic equipment are clear.

From their durability and compact size to their improved signal integrity and cost-effectiveness, rigid-flex PCBs are revolutionizing the way diagnostic equipment is designed and manufactured.

By incorporating these innovative PCBs into their designs, manufacturers can create high-quality, reliable diagnostic equipment that meets the needs of healthcare providers and patients alike.