Benefits of Using Rigid-Flex PCBs in Medical Devices

Design Considerations for Rigid-Flex PCBs in Medical Devices

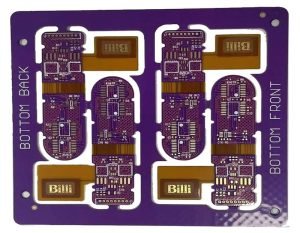

Rigid-flex PCBs, or printed circuit boards, have become increasingly popular in the medical device industry due to their numerous benefits.

These innovative PCBs combine the advantages of both rigid and flexible PCBs, offering a unique solution for medical device manufacturers.

In this article, we will explore the benefits of using rigid-flex PCBs in medical devices and discuss important design considerations to keep in mind when incorporating them into your product.

One of the key benefits of using rigid-flex PCBs in medical devices is their ability to reduce space and weight.

Traditional rigid PCBs require additional connectors and cables to connect different components, which can take up valuable space within a medical device.

Rigid-flex PCBs eliminate the need for these extra components, allowing for a more compact and lightweight design.

This is particularly important in medical devices where size and weight are critical factors, such as wearable devices or implantable devices.

In addition to space and weight savings, rigid-flex PCBs also offer improved reliability.

The flexible portions of the PCB can bend and flex without breaking, reducing the risk of mechanical failure.

This is especially important in medical devices that may be subject to constant movement or vibration.

The rigid portions of the PCB provide stability and support for components, ensuring that they remain securely in place. This combination of flexibility and rigidity results in a more durable and reliable PCB design.

Another benefit of using rigid-flex PCBs in medical devices is their ability to simplify assembly and reduce manufacturing costs.

With fewer components to connect and solder, assembly time is reduced, leading to faster production cycles and lower labor costs.

Additionally, the elimination of connectors and cables reduces the risk of connection errors and improves overall system reliability.

This can be particularly advantageous in high-volume production environments where efficiency and quality control are paramount.

When designing medical devices with rigid-flex PCBs, there are several important considerations to keep in mind.

First and foremost, it is essential to work closely with a qualified PCB manufacturer who has experience in designing and producing rigid-flex PCBs.

They can provide valuable insights and guidance throughout the design process, ensuring that the final product meets all necessary requirements and standards.

It is also important to consider the specific requirements of the medical device when designing the rigid-flex PCB.

Factors such as size, shape, and functionality will all impact the design of the PCB.

For example, implantable medical devices may require a more flexible PCB design to accommodate the body’s movements, while wearable devices may need a more rigid design to withstand daily wear and tear.

Additionally, it is crucial to consider the materials used in the construction of the rigid-flex PCB.

Medical devices must meet strict regulatory standards for safety and reliability, so it is important to use high-quality materials that are compatible with medical applications.

Conductive materials should be biocompatible and non-toxic, and all components should be able to withstand sterilization processes without degradation.

In conclusion, the benefits of using rigid-flex PCBs in medical devices are numerous, including space and weight savings, improved reliability, and simplified assembly.

By carefully considering design considerations such as working with a qualified PCB manufacturer, understanding the specific requirements of the medical device, and selecting high-quality materials, manufacturers can create innovative and reliable medical devices that meet the needs of patients and healthcare providers alike.