Advancements in Materials for Rigid-Flex PCBs

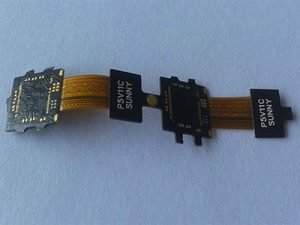

Rigid-flex PCBs have become increasingly popular in the medical industry due to their ability to provide a compact and reliable solution for complex electronic devices.

As technology continues to advance, the demand for more advanced materials in rigid-flex PCB manufacturing for medical applications is also on the rise.

In this article, we will explore some of the future trends in materials for rigid-flex PCBs that are expected to shape the industry in the coming years.

One of the key trends in rigid-flex PCB manufacturing for medical applications is the use of high-performance materials that offer improved reliability and durability.

Traditional materials such as FR-4 have been widely used in the past, but they may not always meet the stringent requirements of medical devices.

As a result, manufacturers are turning to more advanced materials such as polyimide and liquid crystal polymer (LCP) to meet the demands of the medical industry.

Polyimide is a popular choice for rigid-flex PCBs in medical applications due to its high thermal stability, excellent dielectric properties, and resistance to chemicals and moisture.

These properties make polyimide an ideal material for medical devices that need to withstand harsh environments and operate at high temperatures.

In addition, polyimide is also flexible, which allows for greater design flexibility in rigid-flex PCBs.

Liquid crystal polymer (LCP) is another material that is gaining popularity in rigid-flex PCB manufacturing for medical applications.

LCP offers excellent dimensional stability, low moisture absorption, and high chemical resistance, making it an ideal choice for medical devices that require high reliability and performance.

In addition, LCP has a low dielectric constant and loss tangent, which helps to minimize signal loss and interference in rigid-flex PCBs.

Another trend in materials for rigid-flex PCB manufacturing for medical applications is the use of advanced adhesives and bonding materials.

Adhesives play a crucial role in ensuring the reliability and durability of rigid-flex PCBs, as they are used to bond the rigid and flexible layers together.

Traditional adhesives may not always provide the required level of adhesion and reliability, especially in harsh environments.

To address this issue, manufacturers are turning to advanced adhesives such as acrylics, epoxies, and polyimides that offer superior bonding strength, thermal stability, and chemical resistance.

These advanced adhesives help to improve the overall reliability and performance of rigid-flex PCBs in medical applications, ensuring that they can withstand the rigors of the medical environment.

In conclusion, the future trends in materials for rigid-flex PCB manufacturing for medical applications are focused on improving reliability, durability, and performance.

Advanced materials such as polyimide and LCP are being increasingly used to meet the stringent requirements of medical devices, while advanced adhesives are helping to ensure the reliability and durability of rigid-flex PCBs. As technology continues to advance, we can expect to see further innovations in materials for rigid-flex PCB manufacturing that will help to shape the future of the industry.