Benefits of Using Rigid-Flex PCBs in Wearable Medical Devices

Wearable medical devices have revolutionized the way healthcare is delivered, allowing for continuous monitoring of patients’ vital signs and health metrics.

These devices have the potential to improve patient outcomes, reduce healthcare costs, and enhance the overall quality of care.

One key component that has enabled the development of these innovative devices is the use of rigid-flex PCBs.

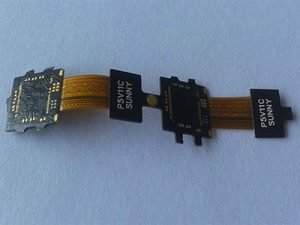

Rigid-flex PCBs, or rigid-flexible printed circuit boards, are a hybrid of traditional rigid PCBs and flexible PCBs.

They combine the best of both worlds, offering the rigidity and durability of a rigid PCB with the flexibility and space-saving benefits of a flexible PCB.

This unique combination makes rigid-flex PCBs ideal for use in wearable medical devices, where space is often limited, and flexibility is essential for comfort and wearability.

One of the key benefits of using rigid-flex PCBs in wearable medical devices is their ability to withstand the rigors of daily use.

Traditional rigid PCBs are prone to damage from bending, twisting, and other forms of mechanical stress.

Flexible PCBs, on the other hand, are more resilient to these types of stresses but lack the rigidity and durability of rigid PCBs.

Rigid-flex PCBs strike the perfect balance, offering the flexibility needed for wearable applications while providing the strength and durability required for long-term reliability.

Another benefit of using rigid-flex PCBs in wearable medical devices is their ability to reduce the overall size and weight of the device.

Traditional rigid PCBs are bulky and inflexible, making them unsuitable for use in small, lightweight devices.

Flexible PCBs are thinner and more lightweight but lack the structural integrity of rigid PCBs.

Rigid-flex PCBs allow designers to create compact, lightweight devices that can be comfortably worn on the body without sacrificing performance or reliability.

In addition to their mechanical advantages, rigid-flex PCBs also offer electrical benefits that make them well-suited for use in wearable medical devices.

The flexible portions of the PCB can be used to route signals between components, reducing the need for bulky connectors and cables.

This not only saves space but also improves signal integrity and reduces the risk of electromagnetic interference.

Rigid-flex PCBs also allow for more complex and compact designs, enabling designers to pack more functionality into a smaller footprint.

Overall, the use of rigid-flex PCBs in wearable medical devices offers a host of benefits that can help drive innovation in the healthcare industry.

These versatile and reliable circuit boards enable the development of smaller, lighter, and more comfortable devices that can be worn discreetly and comfortably by patients.

By combining the best features of rigid and flexible PCBs, rigid-flex PCBs provide the ideal solution for the demanding requirements of wearable medical technologies.

As the demand for wearable medical devices continues to grow, the use of rigid-flex PCBs is likely to become even more prevalent.

Their unique combination of mechanical strength, flexibility, and electrical performance make them an essential component in the development of next-generation healthcare technologies.

With the help of rigid-flex PCBs, wearable medical devices have the potential to revolutionize patient care, improve outcomes, and enhance the overall quality of healthcare delivery.