Benefits of Implementing Rigid Flex PCBs in IoT Devices

The Internet of Things (IoT) has revolutionized the way we interact with technology, allowing for seamless communication between devices and the ability to collect and analyze data in real-time.

As IoT devices become more prevalent in our daily lives, the demand for innovative and reliable printed circuit boards (PCBs) has increased.

Rigid flex PCBs have emerged as a popular choice for IoT implementations due to their unique design and numerous benefits.

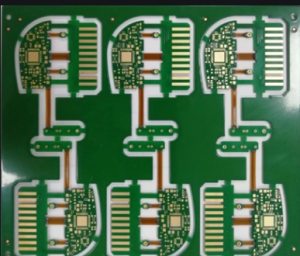

Rigid flex PCBs combine the best of both rigid and flexible PCBs, offering a versatile solution for complex IoT devices.

These boards consist of multiple layers of rigid and flexible materials interconnected through plated through-holes, providing a durable and reliable platform for electronic components.

The flexibility of the PCB allows for intricate designs and compact form factors, making them ideal for IoT devices with limited space constraints.

One of the key benefits of implementing rigid flex PCBs in IoT devices is their enhanced reliability.

Traditional rigid PCBs are prone to mechanical stress and thermal expansion, which can lead to solder joint failures and component damage.

Rigid flex PCBs, on the other hand, are designed to withstand harsh environmental conditions and provide superior mechanical stability.

This increased reliability ensures that IoT devices can operate efficiently and consistently, even in challenging environments.

In addition to reliability, rigid flex PCBs offer improved signal integrity and reduced electromagnetic interference (EMI).

The flexible portions of the PCB act as a shield, minimizing signal distortion and preventing interference from external sources.

This is crucial for IoT devices that rely on accurate data transmission and communication between multiple components.

By using rigid flex PCBs, manufacturers can ensure that their devices maintain optimal performance and connectivity.

Furthermore, rigid flex PCBs enable faster assembly and reduced manufacturing costs for IoT devices.

The integrated design of these boards eliminates the need for additional connectors and cables, streamlining the assembly process and reducing the risk of errors.

This not only saves time but also lowers production costs, making rigid flex PCBs a cost-effective solution for IoT implementations.

To illustrate the benefits of implementing rigid flex PCBs in IoT devices, let’s examine a few case studies of successful implementations.

One example is a smart home security system that utilizes rigid flex PCBs to connect sensors, cameras, and control panels.

The compact design of the PCBs allows for seamless integration of multiple components, resulting in a sleek and efficient system that provides real-time monitoring and alerts to homeowners.

Another case study involves a wearable health monitoring device that incorporates rigid flex PCBs to collect and analyze biometric data.

The flexibility of the PCBs enables the device to conform to the user’s body, ensuring comfort and accuracy during wear.

By using rigid flex PCBs, the manufacturer was able to create a reliable and durable device that delivers precise health insights to users.

In conclusion, the implementation of rigid flex PCBs in IoT devices offers numerous benefits, including enhanced reliability, improved signal integrity, and reduced manufacturing costs.

These boards provide a versatile and efficient platform for complex electronic systems, making them an ideal choice for IoT applications.

By leveraging the advantages of rigid flex PCBs, manufacturers can create innovative and reliable IoT devices that meet the demands of today’s connected world.