The Environmental Impact of Rigid Flex PCB Manufacturing

The rise of the Internet of Things (IoT) has brought about a myriad of benefits and conveniences for consumers and businesses alike.

From smart homes to connected cars, IoT devices have revolutionized the way we live and work.

However, as the demand for these devices continues to grow, so too does the environmental impact of their production.

One area of concern is the manufacturing of rigid flex PCBs, which are essential components in many IoT devices.

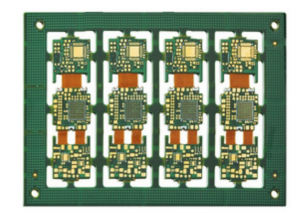

Rigid flex PCBs, or printed circuit boards, are used to connect and support electronic components in IoT devices.

These boards are made up of layers of copper and insulating materials, which are then etched to create the circuitry.

The manufacturing process for rigid flex PCBs involves the use of various chemicals and materials, some of which can have harmful effects on the environment.

One of the main environmental concerns associated with rigid flex PCB manufacturing is the use of hazardous chemicals.

Many of the chemicals used in the etching and plating processes, such as lead, mercury, and cyanide, can be harmful to both human health and the environment.

These chemicals can leach into the soil and water supply, causing pollution and potentially harming wildlife and ecosystems.

In addition to the use of hazardous chemicals, the manufacturing of rigid flex PCBs also requires a significant amount of energy.

The production of these boards involves multiple steps, including etching, plating, and soldering, all of which require energy-intensive processes.

This energy consumption contributes to greenhouse gas emissions and exacerbates climate change.

Furthermore, the disposal of electronic waste, including PCBs, is a growing concern for the environment.

Many IoT devices have a limited lifespan and end up in landfills once they are no longer in use.

PCBs contain materials that can be harmful if not properly disposed of, such as lead and other heavy metals.

Improper disposal of electronic waste can lead to contamination of soil and water sources, posing a risk to human health and the environment.

To address these environmental concerns, manufacturers of rigid flex PCBs must take steps to improve the sustainability of their production processes.

One way to reduce the environmental impact of PCB manufacturing is to use alternative materials that are less harmful to the environment.

For example, manufacturers can explore the use of lead-free solder and other eco-friendly materials in their production processes.

Additionally, manufacturers can implement more efficient manufacturing processes to reduce energy consumption and greenhouse gas emissions.

By optimizing their production processes and investing in energy-efficient technologies, manufacturers can minimize their environmental footprint and contribute to a more sustainable future.

Furthermore, manufacturers can also take steps to improve the recycling and disposal of electronic waste.

By implementing take-back programs and partnering with recycling facilities, manufacturers can ensure that

PCBs and other electronic components are properly recycled and disposed of, reducing the amount of electronic waste that ends up in landfills.

In conclusion, the manufacturing of rigid flex PCBs for IoT devices has a significant environmental impact, from the use of hazardous chemicals to energy consumption and electronic waste disposal.

To address these environmental concerns, manufacturers must prioritize sustainability in their production processes by using alternative materials, reducing energy consumption, and improving electronic waste recycling.

By taking these steps, manufacturers can help mitigate the environmental impact of rigid flex PCB manufacturing and contribute to a more sustainable future for IoT devices.