Benefits of Using Rigid Flex PCBs in Mass Production for IoT Devices

In the rapidly evolving world of technology, the Internet of Things (IoT) has become a ubiquitous presence in our daily lives. From smart homes to wearable devices,

IoT technology is revolutionizing the way we interact with the world around us.

As the demand for IoT devices continues to grow, manufacturers are constantly seeking cost-effective solutions to meet this demand while maintaining high-quality standards.

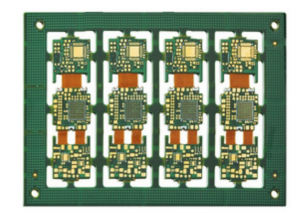

One such solution that has gained popularity in recent years is the use of rigid flex PCBs in mass production for IoT devices.

Rigid flex PCBs, or rigid-flexible printed circuit boards, offer a unique combination of flexibility and durability that make them ideal for use in IoT devices.

These boards consist of a combination of rigid and flexible layers, allowing for greater design flexibility and reliability compared to traditional rigid PCBs.

By incorporating both rigid and flexible elements into a single board, manufacturers can reduce the need for additional connectors and cables, resulting in a more compact and lightweight device.

One of the key benefits of using rigid flex PCBs in mass production for IoT devices is cost-effectiveness.

While the initial cost of manufacturing rigid flex PCBs may be higher than traditional rigid PCBs, the long-term savings can be significant.

By eliminating the need for additional connectors and cables, manufacturers can reduce assembly time and labor costs, resulting in a more streamlined production process.

Additionally, the durability and reliability of rigid flex PCBs can help to reduce maintenance and repair costs over the lifespan of the device.

Another advantage of using rigid flex PCBs in mass production for IoT devices is improved performance and reliability.

The flexible nature of these boards allows for greater design flexibility, enabling manufacturers to create more complex and compact devices.

This can result in improved signal integrity, reduced electromagnetic interference, and enhanced overall performance.

Additionally, the durability of rigid flex PCBs can help to ensure that the device remains reliable and functional even in harsh operating environments.

In addition to cost-effectiveness and improved performance, using rigid flex PCBs in mass production for IoT devices can also help to reduce time-to-market. The flexibility and design capabilities of rigid flex PCBs allow manufacturers to quickly iterate and prototype new designs, speeding up the development process. This can be especially beneficial in the fast-paced world of IoT technology, where time-to-market can be a critical factor in the success of a product.

Overall, the use of rigid flex PCBs in mass production for IoT devices offers a range of benefits that can help manufacturers meet the growing demand for cost-effective, high-quality devices. By combining the flexibility and durability of rigid flex PCBs with the design capabilities and performance improvements they offer, manufacturers can create innovative and reliable IoT devices that meet the needs of consumers. As the IoT market continues to expand, the use of rigid flex PCBs in mass production is likely to become increasingly common as manufacturers seek to stay ahead of the curve and deliver cutting-edge technology to consumers.