Benefits of Using Rigid Flex PCB Technology in IoT Assembly

The Internet of Things (IoT) has revolutionized the way we interact with technology, allowing for seamless communication between devices and systems.

As the demand for IoT devices continues to grow, manufacturers are constantly looking for ways to streamline the assembly process and improve the overall performance of these devices.

One technology that has emerged as a game-changer in IoT assembly is rigid flex PCB technology.

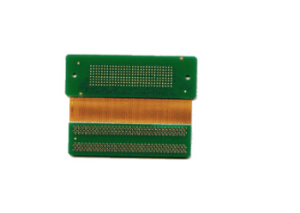

Rigid flex PCBs combine the best of both rigid and flexible circuit boards, offering a unique solution for complex IoT devices.

By integrating rigid and flexible sections into a single board, manufacturers can reduce the number of interconnects and components needed, resulting in a more compact and reliable design.

This not only simplifies the assembly process but also improves the overall durability and performance of the device.

One of the key advantages of using rigid flex PCB technology in IoT assembly is the reduction in size and weight of the device.

Traditional PCBs require multiple interconnects and components, which can take up valuable space and add unnecessary weight to the device.

By using rigid flex PCBs, manufacturers can eliminate the need for bulky connectors and cables, resulting in a more compact and lightweight design.

This is especially important for IoT devices that need to be small and portable, such as wearable technology and smart sensors.

In addition to reducing size and weight, rigid flex PCB technology also offers improved reliability and durability.

The rigid sections of the board provide support and stability for components, while the flexible sections allow for greater flexibility and movement.

This combination of rigidity and flexibility helps to reduce the risk of mechanical failures and ensures that the device can withstand the rigors of everyday use.

This is particularly important for IoT devices that are exposed to harsh environments or constant movement.

Another advantage of using rigid flex PCB technology in IoT assembly is the potential for cost savings.

While the initial investment in rigid flex PCBs may be higher than traditional PCBs, the long-term benefits far outweigh the upfront costs.

By reducing the number of components and interconnects needed, manufacturers can lower assembly time and labor costs.

Additionally, the improved reliability and durability of rigid flex PCBs can help to reduce maintenance and repair costs over the lifetime of the device.

Overall, the advantages of using rigid flex PCB technology in IoT assembly are clear.

From reducing size and weight to improving reliability and durability, rigid flex PCBs offer a unique solution for manufacturers looking to streamline the assembly process and improve the performance of their devices.

With the demand for IoT devices continuing to grow, it is clear that rigid flex PCB technology will play a key role in shaping the future of IoT assembly.