Benefits of Using Rigid Flex PCBs in IoT Devices

The Internet of Things (IoT) has revolutionized the way we interact with technology, allowing for seamless connectivity between devices and the internet.

As IoT devices become more prevalent in our daily lives, the demand for smaller, more efficient, and reliable components has increased.

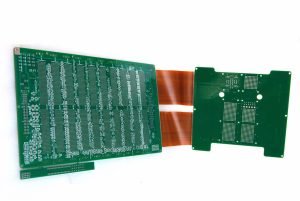

Rigid flex PCBs have emerged as a popular choice for manufacturers looking to meet these demands, offering a unique combination of flexibility and durability that traditional PCBs cannot match.

One of the key benefits of using rigid flex PCBs in IoT devices is their ability to reduce the overall size and weight of the device.

By combining the rigid and flexible portions of the PCB into a single unit, manufacturers can create more compact and lightweight designs that are ideal for space-constrained applications.

This is particularly important in IoT devices, where size and weight are often critical factors in determining the success of a product.

In addition to their compact size, rigid flex PCBs also offer improved reliability compared to traditional PCBs.

The flexible portions of the PCB are less prone to mechanical stress and vibration, reducing the risk of component failure and extending the lifespan of the device.

This is especially important in IoT devices, which are often deployed in harsh environments where traditional PCBs may struggle to maintain their integrity.

Another benefit of using rigid flex PCBs in IoT devices is their ability to simplify the manufacturing process.

By combining the rigid and flexible portions of the PCB into a single unit, manufacturers can reduce the number of components and interconnects required, streamlining the assembly process and reducing the risk of errors.

This not only saves time and money during production but also improves the overall quality and reliability of the finished product.

To take full advantage of the benefits offered by rigid flex PCBs, manufacturers must employ advanced production techniques that are specifically tailored to these unique components.

One such technique is laser drilling, which is used to create small holes in the rigid portions of the PCB to allow for the passage of electrical signals between layers.

Laser drilling is a precise and efficient method that ensures the integrity of the PCB is maintained while also reducing the risk of damage to the flexible portions.

Another important production technique for rigid flex PCBs is controlled impedance routing, which is used to ensure that signals travel at the correct speed and with minimal interference.

By carefully controlling the width and spacing of signal traces, manufacturers can optimize the performance of the PCB and minimize the risk of signal degradation.

This is particularly important in IoT devices, where reliable communication is essential for the device to function properly.

In conclusion, the use of rigid flex PCBs in IoT devices offers a range of benefits, including reduced size and weight, improved reliability, and simplified manufacturing processes.

To fully realize these benefits, manufacturers must employ advanced production techniques such as laser drilling and controlled impedance routing.

By doing so, they can create high-quality, reliable IoT devices that meet the demands of today’s connected world.