Benefits of Customizing Rigid Flex PCBs for Specific Applications

Customization is a key aspect of modern technology, allowing for tailored solutions to meet specific requirements.

When it comes to printed circuit boards (PCBs), customization plays a crucial role in ensuring that devices function optimally in their intended applications.

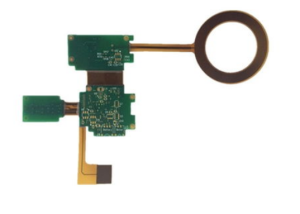

Rigid flex PCBs are a type of PCB that offers the flexibility of a flexible PCB combined with the rigidity of a rigid PCB.

This unique combination makes them ideal for a wide range of applications, from aerospace and defense to medical devices and consumer electronics.

One of the main benefits of customizing rigid flex PCBs for specific applications is the ability to design a PCB that fits the exact dimensions and form factor of the device it will be used in. This level of customization ensures that the PCB will fit seamlessly into the device, maximizing space efficiency and reducing the risk of interference or damage during operation. Additionally, customizing the layout of the PCB allows for optimal placement of components, ensuring that the device functions as intended.

Another benefit of customizing rigid flex PCBs is the ability to tailor the electrical characteristics of the PCB to meet the specific requirements of the device.

By customizing the number of layers, trace widths, and materials used in the PCB, designers can optimize signal integrity, reduce electromagnetic interference, a

nd improve overall performance. This level of customization is especially important in high-speed applications where signal integrity is critical.

Customizing rigid flex PCBs also allows for the integration of additional features and functionality into the device.

For example, designers can incorporate sensors, antennas, or other components directly into the PCB, eliminating the need for additional components and reducing overall complexity. This level of integration not only improves the performance of the device but also reduces manufacturing costs and simplifies assembly processes.

In addition to improving performance and functionality, customizing rigid flex PCBs can also enhance the reliability and durability of the device.

By selecting materials and components that are specifically suited to the intended application, designers can ensure that the PCB will withstand the environmental conditions it will be exposed to. This level of customization is especially important in harsh environments such as aerospace or automotive applications, where reliability is paramount.

Overall, customizing rigid flex PCBs for specific applications offers a wide range of benefits, from improved performance and functionality to enhanced reliability and durability. By tailoring the design of the PCB to meet the exact requirements of the device, designers can ensure that the device will operate optimally in its intended application. Whether it’s optimizing signal integrity in high-speed applications or integrating additional features into the device, customization allows for a level of flexibility and control that is essential in today’s rapidly evolving technology landscape.