Benefits of Flexible Manufacturing for Rigid Flex PCB Production

Flexible manufacturing is a key aspect of modern production processes, allowing companies to adapt to changing demands and requirements.

When it comes to the production of rigid flex PCBs, flexible manufacturing plays a crucial role in accommodating different volumes and designs.

This flexibility enables manufacturers to optimize their production processes, reduce costs, and improve overall efficiency.

One of the main benefits of flexible manufacturing for rigid flex PCB production is the ability to scale production volumes according to demand.

By utilizing flexible manufacturing processes, manufacturers can easily adjust their production capacity to meet changing market conditions.

This means that they can ramp up production during peak periods and scale back during slower times, ensuring that they are able to meet customer demand without incurring unnecessary costs.

In addition to volume flexibility, flexible manufacturing also allows manufacturers to easily accommodate different design requirements.

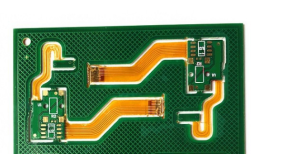

Rigid flex PCBs come in a wide range of shapes, sizes, and configurations, each with its own unique design specifications.

By utilizing flexible manufacturing processes, manufacturers can easily adapt their production lines to accommodate these varying design requirements,

ensuring that they are able to produce high-quality PCBs that meet the needs of their customers.

Another key benefit of flexible manufacturing for rigid flex PCB production is the ability to optimize production processes.

By utilizing flexible manufacturing techniques, manufacturers can identify and eliminate inefficiencies in their production processes, leading to improved productivity and reduced costs.

This optimization can take many forms, from streamlining production workflows to implementing automated manufacturing technologies, all of which can help manufacturers improve their overall efficiency and competitiveness.

Furthermore, flexible manufacturing allows manufacturers to quickly respond to changes in the market or in customer requirements.

In today’s fast-paced business environment, companies need to be able to adapt quickly to changing conditions in order to stay competitive.

By utilizing flexible manufacturing processes, manufacturers can easily pivot their production lines to accommodate new product designs, changes in customer requirements,

or shifts in market demand, ensuring that they are able to stay ahead of the curve and meet the needs of their customers.

Overall, flexible manufacturing is a key enabler of efficient and cost-effective rigid flex PCB production.

By allowing manufacturers to scale production volumes, accommodate different design requirements, optimize production processes, and quickly respond to changes in the market,

flexible manufacturing helps companies stay competitive in today’s fast-paced business environment.

As the demand for rigid flex PCBs continues to grow, manufacturers who embrace flexible manufacturing processes will be well-positioned to capitalize on this trend and drive innovation in the industry.