Benefits of Using Rigid Flex PCBs for Environmental Resistance

In today’s fast-paced world, smart devices have become an integral part of our daily lives.

From smartphones to smartwatches, these devices rely on printed circuit boards (PCBs) to function efficiently.

However, with the increasing demand for smaller and more compact devices, traditional PCBs are often unable to

withstand harsh environmental conditions such as moisture, dust, and chemicals. This is where rigid flex PCBs come into play.

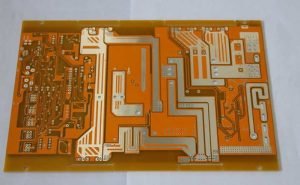

Rigid flex PCBs are a hybrid of rigid and flexible PCBs, offering the best of both worlds.

They consist of multiple layers of rigid and flexible substrates interconnected by plated through-holes, providing a high level of durability and flexibility.

One of the key advantages of using rigid flex PCBs is their ability to resist environmental factors that can damage traditional PCBs.

Moisture is one of the biggest enemies of electronic devices.

When exposed to moisture, traditional PCBs can suffer from corrosion, leading to malfunctions and ultimately device failure.

Rigid flex PCBs, on the other hand, are designed to be resistant to moisture.

By using materials such as polyimide and FR-4, rigid flex PCBs can withstand high levels of humidity without compromising their performance.

This makes them ideal for use in devices that are exposed to moisture, such as wearable technology and outdoor sensors.

In addition to moisture resistance, rigid flex PCBs also offer superior dust resistance.

Dust particles can accumulate on traditional PCBs, causing short circuits and overheating.

Rigid flex PCBs are sealed with protective coatings that prevent dust from entering the board, ensuring that the components remain clean and free from contamination.

This not only enhances the longevity of the device but also improves its overall performance.

Furthermore, rigid flex PCBs are designed to be resistant to chemicals.

In industrial environments where devices are exposed to harsh chemicals, traditional PCBs can deteriorate quickly.

Rigid flex PCBs are made from materials that are chemically resistant,

such as polyimide and epoxy resin, ensuring that they can withstand exposure to a wide range of chemicals without degrading.

This makes them ideal for use in applications where chemical resistance is essential, such as medical devices and industrial equipment.

Overall, the use of rigid flex PCBs for environmental resistance offers a wide range of benefits.

By designing smart devices with rigid flex PCBs, manufacturers can ensure that their products are able to withstand harsh environmental conditions, increasing their longevity and

reliability. Whether it’s moisture, dust, or chemicals, rigid flex PCBs provide a high level of protection that traditional PCBs simply cannot match.

As the demand for smaller and more compact devices continues to grow, the use of rigid flex PCBs will become increasingly important in ensuring that smart devices are able to perform optimally in any environment.