Improved Reliability and Durability

Flex rigid PCBs, also known as flexible printed circuit boards, have become increasingly popular in the medical device industry due to their numerous advantages over traditional rigid PCBs. One of the key benefits of using flex rigid PCBs in medical devices is their improved reliability and durability.

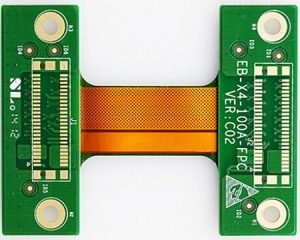

Flex rigid PCBs are designed to be more flexible and resistant to bending and twisting than traditional rigid PCBs. This flexibility allows them to be used in medical devices that require frequent movement or bending, such as wearable medical devices or devices that need to be inserted into the body. The ability of flex rigid PCBs to withstand repeated bending and flexing without breaking or losing functionality makes them ideal for use in medical devices that need to be durable and reliable.

In addition to their flexibility, flex rigid PCBs are also more resistant to shock and vibration than traditional rigid PCBs. This makes them ideal for use in medical devices that are subject to rough handling or that need to operate in harsh environments. The increased shock and vibration resistance of flex rigid PCBs helps to ensure that the components of the medical device remain securely connected and functioning properly, even in challenging conditions.

Another advantage of using flex rigid PCBs in medical devices is their compact size and lightweight design. Flex rigid PCBs can be designed to fit into tight spaces and conform to the shape of the device, allowing for more efficient use of space and reducing the overall size and weight of the device. This is particularly important in medical devices that need to be portable or wearable, as smaller and lighter devices are more comfortable for patients to use and easier for healthcare providers to transport and handle.

Furthermore, the use of flex rigid PCBs in medical devices can also help to reduce the overall cost of manufacturing and assembly. Flex rigid PCBs can be designed to include multiple layers of circuitry in a single board, eliminating the need for multiple separate boards and reducing the complexity of the device. This simplification of the design and assembly process can lead to cost savings in terms of materials, labor, and production time, making flex rigid PCBs a cost-effective choice for medical device manufacturers.

Overall, the advantages of using flex rigid PCBs in medical devices are clear. Their improved reliability and durability, shock and vibration resistance, compact size and lightweight design, and cost-effectiveness make them an ideal choice for a wide range of medical applications. As the demand for smaller, more portable, and more reliable medical devices continues to grow, flex rigid PCBs are likely to play an increasingly important role in the development of innovative new medical technologies. By incorporating flex rigid PCBs into their designs, medical device manufacturers can create devices that are not only more reliable and durable but also more efficient, cost-effective, and user-friendly.