Benefits of Using Flex Rigid PCBs in Automotive Electronics

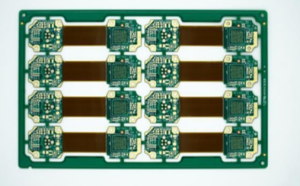

Flex rigid PCBs, also known as flexible printed circuit boards, are becoming increasingly popular in automotive applications due to their numerous benefits. These innovative PCBs offer a combination of flexibility and rigidity, making them ideal for use in vehicles where space is limited and durability is essential.

One of the key benefits of using flex rigid PCBs in automotive electronics is their ability to withstand harsh environmental conditions. Vehicles are exposed to extreme temperatures, vibrations, and moisture, which can damage traditional rigid PCBs. Flex rigid PCBs, on the other hand, are designed to be more resilient, making them a reliable choice for automotive applications.

In addition to their durability, flex rigid PCBs offer a significant space-saving advantage. In modern vehicles, space is at a premium, and traditional rigid PCBs can be bulky and difficult to fit into tight spaces. Flex rigid PCBs, with their flexible design, can be bent and shaped to fit into smaller areas, allowing for more efficient use of space in automotive electronics.

Another benefit of using flex rigid PCBs in automotive applications is their ability to reduce the overall weight of the vehicle. Traditional rigid PCBs are heavier and can add unnecessary weight to the vehicle, which can impact fuel efficiency and performance. Flex rigid PCBs are lighter and more compact, helping to reduce the overall weight of the vehicle without sacrificing functionality.

Furthermore, flex rigid PCBs offer improved signal integrity and reliability compared to traditional rigid PCBs. The flexible design of flex rigid PCBs reduces the risk of signal interference and crosstalk, resulting in more stable and reliable performance in automotive electronics. This is crucial in vehicles where safety and reliability are paramount.

Flex rigid PCBs also offer greater design flexibility, allowing for more complex and compact electronic systems to be integrated into vehicles. This flexibility enables automotive manufacturers to create innovative and advanced electronic systems that enhance the overall performance and functionality of the vehicle.

Overall, the benefits of using flex rigid PCBs in automotive electronics are clear. From their durability and space-saving advantages to their weight reduction and improved signal integrity, flex rigid PCBs offer a range of benefits that make them an ideal choice for automotive applications. As vehicles become more advanced and electronic systems become more complex, flex rigid PCBs will continue to play a crucial role in shaping the future of automotive electronics.