Strategies for Improving Yield Rates in Rigid-Flex PCB Assembly

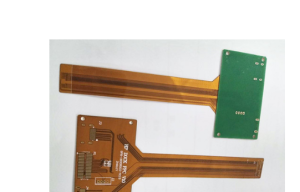

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to reduce space and weight in electronic devices.

However, the assembly and testing of rigid-flex PCBs present unique challenges that can impact yield rates if not properly addressed.

In this article, we will discuss some strategies for overcoming these challenges and improving yield rates in rigid-flex PCB assembly.

One of the main challenges in rigid-flex PCB assembly is ensuring proper alignment of the rigid and flexible sections during the lamination process.

Misalignment can lead to defects such as wrinkles or delamination, which can affect the functionality of the PCB. To address this challenge, it is important to use precise alignment tools and techniques,

such as laser drilling or automated optical inspection systems, to ensure that the rigid and flexible sections are properly aligned before lamination.

Another challenge in rigid-flex PCB assembly is managing the thermal stresses that can occur during the soldering process.

The combination of rigid and flexible materials in a single PCB can result in uneven heating and cooling, which can lead to warping or cracking of the PCB.

To mitigate this risk, it is important to use controlled heating and cooling processes, such as reflow ovens with multiple heating zones, to ensure that the temperature is evenly distributed across the PCB during soldering.

In addition to assembly challenges, testing rigid-flex PCBs can also be more complex than testing traditional rigid PCBs.

The flexible sections of a rigid-flex PCB can be more susceptible to damage during testing, which can result in lower yield rates.

To address this challenge, it is important to use specialized testing equipment, such as bend testers or impedance analyzers, to ensure that the flexible sections of the PCB are not damaged during testing.

Furthermore, it is important to conduct thorough testing of both the rigid and flexible sections of the PCB to ensure that all components are functioning properly.

This may require the use of specialized test fixtures or custom test programs to accommodate the unique design of rigid-flex PCBs.

By investing in the right testing equipment and procedures, manufacturers can improve yield rates and ensure the reliability of their rigid-flex PCBs.

In conclusion, overcoming the challenges in rigid-flex PCB assembly and testing requires a combination of precision, control, and specialized equipment.

By using precise alignment tools, controlled heating and cooling processes, and specialized testing equipment, manufacturers can improve yield rates and ensure the reliability of their rigid-flex PCBs.

With the right strategies in place, manufacturers can successfully navigate the complexities of rigid-flex PCB assembly and testing and deliver high-quality products to their customers.