Emerging Technologies in Rigid Flex Assembly

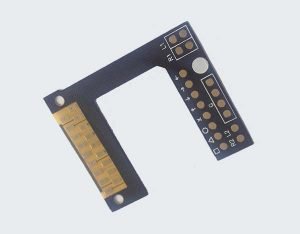

Rigid-flex assembly is a cutting-edge technology that combines the benefits of rigid and flexible printed circuit boards (PCBs) into a single unit.

This innovative approach allows for greater design flexibility, reduced weight, and improved reliability in electronic devices.

As the demand for smaller, lighter, and more durable electronics continues to grow, rigid-flex assembly has become increasingly popular in a wide range of industries,

including aerospace, medical devices, and consumer electronics.

One of the key trends in rigid-flex assembly is the use of advanced materials to improve performance and reliability.

Manufacturers are constantly exploring new materials that offer better thermal stability, higher flexibility, and increased resistance to environmental factors such as moisture and vibration.

By using these materials, engineers can design more robust and reliable rigid-flex assemblies that can withstand the rigors of everyday use.

Another important trend in rigid-flex assembly is the development of innovative manufacturing techniques that allow for faster production and lower costs.

One such technique is the use of additive manufacturing, also known as 3D printing, to create complex rigid-flex assemblies in a single step. This approach eliminates the need

for multiple manufacturing processes and reduces the time and cost associated with traditional assembly methods.

In addition to advanced materials and manufacturing techniques, the integration of smart technologies such as sensors and wireless communication capabilities is also driving innovation in rigid-flex assembly. These technologies enable electronic devices to collect and transmit data in real-time, opening up new possibilities for applications in the Internet of Things (IoT) and other emerging technologies.

As the demand for smaller, lighter, and more reliable electronics continues to grow, manufacturers are constantly pushing the boundaries of what is possible with rigid-flex assembly.

By staying at the forefront of these trends and innovations, companies can develop cutting-edge products that meet the needs of today’s consumers while also preparing for the challenges of tomorrow.

In conclusion, rigid-flex assembly is a rapidly evolving technology that offers numerous benefits for electronic device manufacturers.

By incorporating advanced materials, innovative manufacturing techniques, and smart technologies, companies can create products that are smaller, lighter, and more reliable than ever before.

As the demand for these products continues to grow, it is essential for manufacturers to stay ahead of the curve and embrace the latest trends and innovations in rigid-flex assembly.

By doing so, they can position themselves as leaders in the industry and meet the needs of today’s consumers while also preparing for the challenges of tomorrow.