Benefits of Rigid Flex PCBs

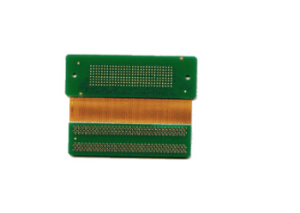

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their numerous benefits. These innovative circuit boards combine the advantages of both rigid and flexible PCBs, offering a unique solution for applications that require a combination of flexibility and durability.

In this article, we will delve into the manufacturing processes involved in producing rigid-flex PCBs, shedding light on the intricate steps that go into creating these advanced circuit boards.

The manufacturing of rigid-flex PCBs is a complex process that requires precision and expertise. The first step in the manufacturing process is designing the circuit layout. Designers must carefully plan the placement of components and traces to ensure optimal performance and reliability. Once the design is finalized, it is transferred to a computer-aided design (CAD) software, where it is converted into a digital file that will be used to create the PCB.

The next step in the manufacturing process is printing the circuit layout onto a substrate material. This is typically done using a process called screen printing, where a stencil is used to apply a conductive ink onto the substrate. The conductive ink forms the traces and pads that will carry electrical signals throughout the PCB. After the circuit layout has been printed, the substrate is cured in an oven to ensure that the conductive ink adheres properly.

Once the circuit layout has been printed and cured, the next step is to laminate the layers together. Rigid-flex PCBs consist of multiple layers of rigid and flexible materials that are bonded together using a combination of heat and pressure. This process creates a strong and durable bond between the layers, ensuring that the PCB can withstand the rigors of everyday use.

After the layers have been laminated together, the next step is to drill holes for the components. This is done using a precision drilling machine that creates holes of varying sizes to accommodate different component sizes. Once the holes have been drilled, the next step is to plate them with a conductive material to ensure proper electrical connections.

The final step in the manufacturing process is to assemble the components onto the PCB. This is typically done using automated pick-and-place machines that accurately position each component onto the board. Once all the components have been placed, the PCB is soldered to create permanent connections between the components and the traces.

In conclusion, the manufacturing of rigid-flex PCBs is a complex process that requires precision and expertise. From designing the circuit layout to assembling the components, each step in the manufacturing process plays a crucial role in creating a high-quality PCB. By understanding the intricacies of the manufacturing process, we can gain a greater appreciation for the advanced technology that goes into producing rigid-flex PCBs.