Improved Reliability and Durability

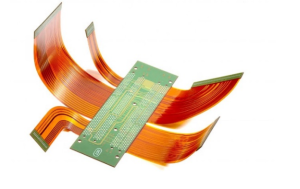

Printed circuit boards (PCBs) are an essential component in electronic devices, providing the necessary connections between various electronic components. Traditional PCBs are rigid and inflexible, limiting their use in devices that require flexibility or compactness. However, the development of rigid flex PCBs has revolutionized the electronics industry by combining the benefits of both rigid and flexible PCBs. In this article, we will explore the benefits of rigid flex PCBs, focusing on their improved reliability and durability.

One of the key advantages of rigid flex PCBs is their enhanced reliability. Traditional PCBs are prone to failure due to the stress caused by bending or flexing, especially in devices that undergo frequent movement or vibration. Rigid flex PCBs, on the other hand, are designed to withstand bending and flexing without compromising their structural integrity. This makes them ideal for use in devices such as smartphones, tablets, and wearable technology, where flexibility is essential.

In addition to improved reliability, rigid flex PCBs also offer enhanced durability. The flexible portion of the PCB is made from a polyimide material that is highly resistant to heat, chemicals, and moisture. This ensures that the PCB can withstand harsh environmental conditions without deteriorating or malfunctioning. As a result, devices equipped with rigid flex PCBs are more durable and long-lasting, reducing the need for frequent repairs or replacements.

Furthermore, rigid flex PCBs are more compact and lightweight than traditional PCBs, making them ideal for use in devices with limited space. The flexible portion of the PCB can be folded or bent to fit into tight spaces, allowing for more efficient use of available space within the device. This not only improves the overall design and aesthetics of the device but also reduces the overall weight, making it more portable and convenient for users.

Another benefit of rigid flex PCBs is their cost-effectiveness. While the initial cost of manufacturing rigid flex PCBs may be higher than traditional PCBs, the long-term savings are significant. The enhanced reliability and durability of rigid flex PCBs result in fewer repairs and replacements, reducing maintenance costs over the lifespan of the device. Additionally, the compact design of rigid flex PCBs allows for more efficient use of space, reducing the overall size and weight of the device, which can lead to cost savings in materials and manufacturing.

In conclusion, rigid flex PCBs offer a wide range of benefits, including improved reliability, durability, compactness, and cost-effectiveness. These advantages make them an ideal choice for electronic devices that require flexibility, compactness, and reliability. As the demand for smaller, more flexible electronic devices continues to grow, rigid flex PCBs are likely to become increasingly popular in a wide range of applications. By investing in rigid flex PCB technology, manufacturers can ensure that their devices are not only more reliable and durable but also more cost-effective and efficient in the long run.