Benefits of Rigid Flex PCBs

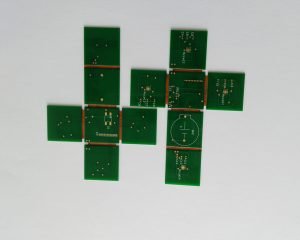

Printed circuit boards (PCBs) are an essential component in many electronic devices, providing a platform for connecting various electronic components. Traditionally, PCBs have been rigid, meaning they are made from solid materials that do not bend or flex. However, in recent years, there has been a growing demand for flexible PCBs, known as rigid flex PCBs. These boards offer a combination of rigid and flexible materials, providing unique benefits that traditional PCBs cannot match.

One of the key benefits of rigid flex PCBs is their ability to save space in electronic devices. Traditional PCBs are limited by their rigid nature, requiring additional connectors and cables to link different sections of the board. In contrast, rigid flex PCBs can be designed to fit into tight spaces and follow the contours of the device, eliminating the need for bulky connectors and cables. This not only reduces the overall size of the device but also improves its reliability by minimizing the number of potential points of failure.

Another advantage of rigid flex PCBs is their enhanced durability. Traditional PCBs are susceptible to damage from bending, twisting, and vibration, which can lead to broken connections and malfunctioning components. Rigid flex PCBs, on the other hand, are designed to withstand these stresses, thanks to the flexible materials that allow them to bend and flex without compromising their structural integrity. This makes them ideal for use in applications where the device is subject to frequent movement or harsh environmental conditions.

In addition to their space-saving and durability benefits, rigid flex PCBs also offer improved signal integrity. Traditional PCBs can suffer from signal loss and interference due to the use of connectors and cables, which introduce resistance and capacitance into the circuit. Rigid flex PCBs eliminate the need for these additional components, providing a more direct and reliable connection between electronic components. This results in better signal quality, reduced electromagnetic interference, and improved overall performance of the device.

Furthermore, rigid flex PCBs are more cost-effective in the long run. While the initial manufacturing costs of rigid flex PCBs may be higher than traditional PCBs, the savings in space, materials, and labor can outweigh this initial investment. By eliminating the need for connectors, cables, and additional components, rigid flex PCBs reduce the overall bill of materials and assembly time, resulting in lower production costs and a more efficient manufacturing process.

Overall, the benefits of rigid flex PCBs make them a compelling choice for a wide range of electronic applications. From smartphones and wearables to medical devices and aerospace systems, rigid flex PCBs offer a unique combination of space-saving design, durability, signal integrity, and cost-effectiveness that traditional PCBs cannot match. By understanding the differences between rigid flex PCBs and traditional PCBs, designers and engineers can make informed decisions about which type of board is best suited for their specific application.