Benefits of Integrating Rigid-Flexible PCBs in Electronics Manufacturing

In the world of electronics manufacturing, the demand for smaller, lighter, and more complex devices continues to grow.

As a result, manufacturers are constantly seeking ways to streamline their processes and improve efficiency.

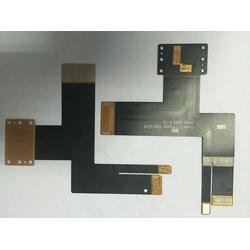

One way to achieve this is by integrating rigid-flexible printed circuit boards (PCBs) into their designs.

Rigid-flex PCBs offer a unique combination of flexibility and rigidity, allowing for more compact and lightweight designs.

By eliminating the need for bulky connectors and cables, rigid-flex PCBs can reduce the overall size and weight of a device,

making it more portable and easier to handle.

In addition to their physical benefits, rigid-flex PCBs also offer improved reliability and durability.

Traditional PCBs are prone to failure due to the constant bending and flexing that occurs during use.

Rigid-flex PCBs, on the other hand, are designed to withstand these stresses, resulting in a longer lifespan and reduced maintenance costs.

Another advantage of integrating rigid-flex PCBs into electronics manufacturing is the ability to streamline the assembly process.

Traditional PCBs require multiple steps to connect the various components, including soldering, wiring, and testing. With rigid-flex PCBs,

many of these steps can be eliminated, reducing the overall assembly time and cost.

Furthermore, rigid-flex PCBs can improve the overall performance of a device.

By reducing the number of interconnects and improving signal integrity, rigid-flex PCBs can help to

minimize signal loss and interference,resulting in a more reliable and efficient product.

One of the key benefits of integrating rigid-flex PCBs into electronics manufacturing is the ability to customize designs to meet specific requirements.

Rigid-flex PCBs can be tailored to fit the unique shape and size of a device, allowing for more creative and innovative designs.

This flexibility can help manufacturers to differentiate their products in a competitive market and meet the evolving needs of consumers.

In conclusion, the integration of rigid-flex PCBs into electronics manufacturing offers a wide range of benefits, including improved reliability, durability, performance, and customization. By streamlining the assembly process and reducing the overall size and weight of a device, rigid-flex PCBs can help manufacturers to create more compact, lightweight, and efficient products.

As the demand for smaller, lighter, and more complex devices continues to grow, rigid-flex PCBs are becoming an essential component of modern electronics manufacturing.