Benefits of Using Rigid-Flexible PCBs in SMT Assembly Integration

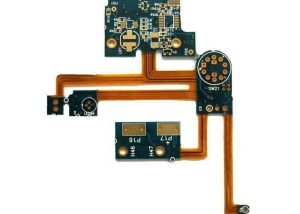

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These boards are designed to be more compact, lightweight, and durable than traditional PCBs, making them ideal for a wide range of applications.

One area where rigid-flex PCBs excel is in surface mount technology (SMT) assembly integration.

One of the key benefits of using rigid-flex PCBs in SMT assembly integration is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible sections in a single board, designers can create more compact and lightweight products without sacrificing functionality.

This is particularly important in industries where space is limited, such as aerospace, automotive, and medical devices.

Another advantage of rigid-flex PCBs in SMT assembly integration is their improved reliability. Traditional PCBs are prone to mechanical stress and vibration, which can lead to solder joint failures and other reliability issues. Rigid-flex PCBs, on the other hand, are designed to be more resistant to these types of stresses, resulting in a more reliable and durable product.

In addition to their size, weight, and reliability benefits, rigid-flex PCBs also offer greater design flexibility. Designers can create complex, three-dimensional shapes that would be impossible with traditional PCBs, allowing for more creative and innovative product designs. This flexibility is particularly useful in applications where space is limited or where the PCB needs to conform to a specific shape or size.

Furthermore, rigid-flex PCBs can help streamline the SMT assembly process. Because these boards are designed to be more compact and lightweight, they are easier to handle and assemble than traditional PCBs. This can lead to faster production times and lower manufacturing costs, making rigid-flex PCBs a cost-effective solution for many companies.

Overall, the benefits of using rigid-flex PCBs in SMT assembly integration are clear. These boards offer a combination of size, weight, reliability, and design flexibility that is unmatched by traditional PCBs. By incorporating rigid-flex PCBs into their designs, companies can create more compact, lightweight, and reliable products that are easier and more cost-effective to manufacture.

In conclusion, rigid-flex PCBs are a versatile and innovative solution for SMT assembly integration. Their unique combination of rigid and flexible sections offers a range of benefits, including reduced size and weight, improved reliability, greater design flexibility, and streamlined assembly processes. By incorporating rigid-flex PCBs into their designs, companies can create more compact, lightweight, and reliable products that are easier and more cost-effective to manufacture.