Benefits of Using Rigid-Flexible PCBs in SMT Assembly Processes

Printed circuit boards (PCBs) are an essential component in the electronics industry, serving as the foundation for connecting various electronic components in devices such as smartphones, computers, and medical equipment. Traditionally, PCBs have been manufactured using rigid materials such as fiberglass or epoxy resin. However, with the advancement of technology and the demand for smaller, lighter, and more flexible electronic devices, the use of rigid-flex PCBs has become increasingly popular.

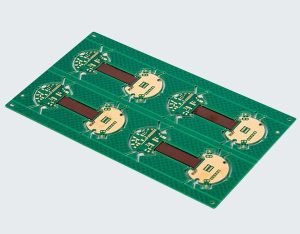

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs, offering a unique solution for applications that require a combination of flexibility and durability. These boards consist of multiple layers of flexible circuitry interconnected with rigid sections, allowing for complex designs that can be folded or bent to fit into tight spaces. The flexibility of these boards also reduces the need for additional connectors and cables, resulting in a more compact and reliable electronic device.

One of the key advantages of using rigid-flex PCBs in surface mount technology (SMT) assembly processes is the improved reliability and durability of the final product. The flexible nature of these boards allows for better shock and vibration resistance, making them ideal for applications in industries such as aerospace, automotive, and medical devices where reliability is critical. Additionally, the elimination of connectors and cables reduces the risk of signal interference and improves signal integrity, resulting in a more stable and efficient electronic device.

Another benefit of using rigid-flex PCBs in SMT assembly processes is the reduction in assembly time and cost. Traditional PCBs require multiple components to be soldered onto the board, which can be time-consuming and labor-intensive. In contrast, rigid-flex PCBs allow for components to be mounted directly onto the board, reducing the number of solder joints and assembly steps required. This not only speeds up the assembly process but also reduces the risk of human error and improves overall product quality.

Furthermore, the use of rigid-flex PCBs in SMT assembly processes can lead to a more streamlined and compact design. The ability to bend or fold the board allows for more creative and space-saving layouts, enabling designers to create smaller and more lightweight electronic devices. This is particularly advantageous in applications where size and weight are critical factors, such as wearable technology, IoT devices, and portable medical equipment.

In conclusion, the intersection of rigid-flex PCBs and SMT assembly processes offers numerous benefits for electronic device manufacturers.

From improved reliability and durability to reduced assembly time and cost, the use of rigid-flex PCBs can help companies stay competitive in a rapidly

evolving industry. By embracing this innovative technology, manufacturers can create more reliable, efficient, and compact electronic devices that meet the demands of today’s consumers.