Design Considerations for Rigid-Flexible PCBs

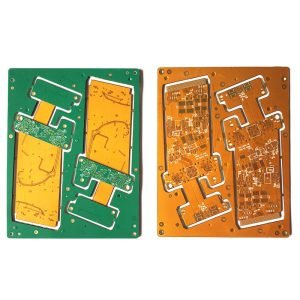

Rigid-flex PCBs, a combination of rigid and flexible circuit boards, have become increasingly popular in the electronics industry due to their ability to save space, reduce weight, and improve reliability. However, designing these complex boards comes with its own set of challenges that engineers must overcome to ensure a successful product. In this article, we will explore some of the key design considerations for rigid-flex PCBs and discuss potential solutions to common challenges.

One of the main challenges in designing rigid-flex PCBs is ensuring proper signal integrity. The combination of rigid and flexible sections can introduce impedance variations, signal reflections, and crosstalk, which can degrade the performance of the circuit. To address these issues, designers must carefully plan the routing of high-speed signals, minimize signal length mismatches, and use impedance-controlled traces to maintain signal integrity throughout the board.

Another challenge in designing rigid-flex PCBs is managing thermal issues. The different materials used in rigid and flexible sections have different thermal properties, which can lead to uneven heat distribution and thermal stress. To prevent overheating and ensure reliable operation, designers must carefully consider the placement of components, use thermal vias to dissipate heat, and incorporate thermal relief patterns to minimize thermal stress on the board.

Mechanical reliability is also a critical consideration when designing rigid-flex PCBs. The bending and flexing of the board during assembly, installation, and operation can put stress on the components and traces, leading to mechanical failures. To improve the mechanical reliability of the board, designers must carefully select materials with good flexibility and durability, use proper bending radius guidelines, and reinforce critical areas with additional support structures or stiffeners.

Furthermore, designing rigid-flex PCBs requires careful attention to manufacturing constraints. The combination of rigid and flexible sections can complicate the manufacturing process, making it more challenging to ensure proper alignment, registration, and bonding between the different layers.

To address these challenges, designers must work closely with manufacturers to optimize the fabrication process, use proper design for manufacturability guidelines, and conduct thorough design reviews to identify and address potential manufacturing issues early in the design process.

In conclusion, designing rigid-flex PCBs presents a unique set of challenges that engineers must overcome to ensure a successful product.

By carefully considering signal integrity, thermal management, mechanical reliability, and manufacturing constraints, designers can create robust and reliable rigid-flex PCBs that meet the performance requirements of modern electronic devices. With proper planning, collaboration, and attention to detail, engineers can overcome these challenges and unlock the full potential of rigid-flex PCB technology for a wide range of applications.