Design Considerations for Rigid-Flexible PCBs

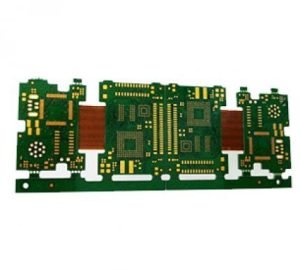

Rigid-flex PCBs, a combination of rigid and flexible circuit boards, have become increasingly popular in the electronics industry due to their ability to save space, reduce weight, and improve reliability. Designing a rigid-flex PCB requires careful consideration of various factors to ensure optimal performance and functionality. In this article, we will discuss some key design considerations for rigid-flex PCBs, from concept to completion.

One of the first considerations when designing a rigid-flex PCB is the overall form factor and layout. The combination of rigid and flexible sections allows for greater design flexibility, but it also presents challenges in terms of routing and placement of components. Careful planning is required to ensure that the rigid and flexible sections are seamlessly integrated to meet the specific requirements of the application.

Another important consideration is the selection of materials for the rigid and flexible sections of the PCB. The choice of materials will impact the overall performance and reliability of the PCB. For example, flexible materials such as polyimide offer excellent flexibility and durability, while rigid materials like FR4 provide stability and support for components. It is essential to select materials that are compatible with each other and can withstand the environmental conditions in which the PCB will be used.

In addition to materials, the design of the stack-up is crucial in rigid-flex PCBs. The stack-up refers to the arrangement of layers in the PCB, including the rigid and flexible sections. Proper stack-up design is essential for signal integrity, impedance control, and thermal management. It is important to work closely with the PCB manufacturer to develop a stack-up that meets the specific requirements of the design.

Signal integrity is another critical consideration in rigid-flex PCB design. The combination of rigid and flexible sections can introduce impedance variations and signal distortions if not properly managed. Careful routing and placement of signal traces, as well as the use of impedance-controlled design techniques, are essential to ensure signal integrity and minimize signal loss.

Thermal management is also a key consideration in rigid-flex PCB design. The combination of rigid and flexible sections can create thermal hotspots that can affect the performance and reliability of the PCB. Proper placement of components, vias, and thermal vias, as well as the use of thermal relief patterns, are essential to dissipate heat and maintain optimal operating temperatures.

Finally, testing and validation are crucial steps in the design process of rigid-flex PCBs. Comprehensive testing, including electrical testing, thermal testing, and mechanical testing, is essential to ensure that the PCB meets the specified requirements and performs as intended. It is important to work closely with the PCB manufacturer to develop a testing plan that addresses all aspects of the design.

In conclusion, designing a rigid-flex PCB requires careful consideration of various factors, from form factor and layout to materials, stack-up, signal integrity, thermal management, and testing. By addressing these key design considerations, engineers can develop high-quality rigid-flex PCBs that meet the specific requirements of the application and deliver optimal performance and reliability. Working closely with experienced PCB manufacturers and following best practices in design and testing will help ensure the successful completion of rigid-flex PCB projects.