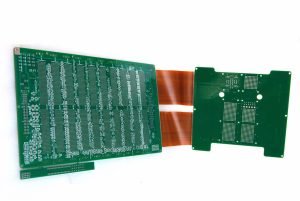

Advancements in Flex Rigid PCB Manufacturing Techniques

Flex rigid PCB technology has been rapidly evolving in recent years, with new advancements and updates being introduced on a regular basis.

This month, we are excited to share some of the latest developments in flex rigid PCB manufacturing techniques that are pushing the boundaries of what is possible in the world of electronics.

One of the most significant updates in flex rigid PCB technology this month is the introduction of advanced materials that offer improved flexibility and durability. These new materials are designed to withstand the rigors of modern electronics applications, including high temperatures, moisture, and mechanical stress. By using these advanced materials, manufacturers can create flex rigid PCBs that are more reliable and long-lasting than ever before.

In addition to improved materials, manufacturers are also exploring new manufacturing techniques that allow for greater precision and efficiency in the production of flex rigid PCBs. One such technique is laser drilling, which enables manufacturers to create smaller and more intricate designs with higher levels of accuracy. By using laser drilling, manufacturers can achieve tighter tolerances and more complex designs, leading to improved performance and reliability in flex rigid PCBs.

Another key advancement in flex rigid PCB technology this month is the integration of advanced testing and inspection processes into the manufacturing workflow. By implementing automated testing and inspection systems, manufacturers can ensure that each flex rigid PCB meets the highest quality standards before it is shipped to customers. This helps to reduce the risk of defects and failures in the field, leading to improved customer satisfaction and lower overall costs for manufacturers.

Furthermore, manufacturers are also exploring new ways to improve the overall efficiency of the flex rigid PCB manufacturing process.

One such innovation is the use of advanced automation systems that streamline production and reduce the need for manual labor.

By automating key processes such as soldering, assembly, and testing, manufacturers can increase throughput and reduce lead times,

allowing them to deliver products to market faster and more cost-effectively.

Overall, the latest updates in flex rigid PCB technology are driving significant advancements in the industry, with improved materials, manufacturing techniques, testing processes, and automation systems all contributing to higher levels of performance and reliability in flex rigid PCBs.

As manufacturers continue to push the boundaries of what is possible in flex rigid PCB technology, we can expect to see even more exciting developments in the months and years to come.

In conclusion, the advancements in flex rigid PCB manufacturing techniques this month are setting the stage for a new era of innovation and progress in the electronics industry. By leveraging advanced materials, manufacturing techniques, testing processes, and automation systems, manufacturers are able to create flex rigid PCBs that are more reliable, durable, and efficient than ever before. As we look to the future, it is clear that flex rigid PCB technology will continue to play a crucial role in powering the next generation of electronic devices and systems.