Advancements in Flex Rigid PCB Manufacturing Processes

Flex rigid PCB technology has seen significant advancements in recent years, revolutionizing the way electronic devices are designed and manufactured.

These breakthroughs have opened up new possibilities for creating smaller, lighter, and more flexible devices that can be used in a wide range of applications.

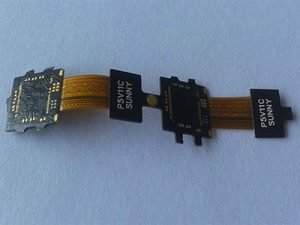

One of the key advancements in flex rigid PCB technology is the development of new manufacturing processes that allow for greater flexibility and durability in the final product. Traditional PCBs are made from rigid materials such as fiberglass, which limits their flexibility and makes them unsuitable for use in devices that need to bend or flex. However, with the introduction of flex rigid PCBs, manufacturers can now create boards that combine the flexibility of a flexible PCB with the durability of a rigid PCB.

These new manufacturing processes involve the use of specialized materials and techniques that allow for the creation of boards with multiple layers of flexible and rigid materials. This allows for greater design flexibility and the ability to create complex, three-dimensional shapes that would be impossible with traditional PCBs. In addition, these new processes also allow for the integration of components directly onto the board, reducing the need for additional wiring and making the final product more compact and lightweight.

Another key advancement in flex rigid PCB technology is the development of new materials that offer improved performance and reliability.

Traditional PCB materials can be prone to issues such as delamination, cracking, and warping, especially when subjected to extreme temperatures or mechanical stress. However, with the introduction of new materials such as polyimide and liquid crystal polymer, manufacturers can now create boards that are more resistant to these issues and offer greater reliability in a wider range of operating conditions.

These new materials also offer improved electrical performance, with lower signal loss and better impedance control than traditional materials.

This allows for faster data transfer rates and more reliable operation in high-speed applications. In addition, these materials are also more environmentally friendly, with lower levels of toxic chemicals and reduced energy consumption during the manufacturing process.

In addition to advancements in manufacturing processes and materials, there have also been significant improvements in the design and layout of flex rigid PCBs. Design software has become more sophisticated, allowing for greater control over the placement of components and routing of traces. This has led to more efficient designs that minimize signal interference and reduce the overall size of the board.

Furthermore, advancements in 3D printing technology have also had a significant impact on flex rigid PCB manufacturing.

3D printing allows for the creation of complex, custom shapes that would be impossible to achieve with traditional manufacturing techniques.

This has opened up new possibilities for creating innovative designs that push the boundaries of what is possible with flex rigid PCB technology.

Overall, the latest breakthroughs in flex rigid PCB technology have paved the way for a new generation of electronic devices that are smaller, lighter, and more flexible than ever before. With improved manufacturing processes, materials, design software, and 3D printing technology, manufacturers can now create boards that offer greater performance, reliability, and design flexibility. As the demand for smaller, more powerful electronic devices continues to grow, flex rigid PCB technology will play an increasingly important role in shaping the future of electronics.