Advancements in Flex Rigid PCB Technology: Breaking News for This Month

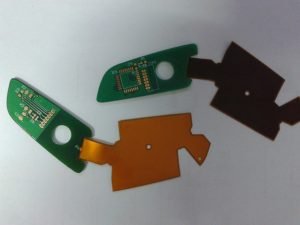

Flex rigid PCB technology has been making waves in the electronics industry for its ability to combine the flexibility of a flexible PCB with the durability of a rigid PCB. This innovative technology has opened up new possibilities for designers and engineers looking to create more compact and reliable electronic devices. This month, there have been some exciting developments in flex rigid PCB technology that are worth noting.

One of the most significant advancements in flex rigid PCB technology this month is the introduction of new materials that offer improved performance and reliability. These new materials have been specifically designed to enhance the flexibility and durability of flex rigid PCBs, making them even more versatile for a wide range of applications. By using these new materials, designers can create electronic devices that are not only smaller and lighter but also more resistant to environmental factors such as moisture and temperature fluctuations.

In addition to new materials, there have also been advancements in the manufacturing processes used to produce flex rigid PCBs.

These new processes have been developed to improve the efficiency and accuracy of PCB production, resulting in higher quality and more reliable products. By streamlining the manufacturing process, companies can reduce production costs and lead times, making flex rigid PCB technology more accessible to a wider range of industries.

Another exciting development in flex rigid PCB technology this month is the introduction of new design software that makes it easier for designers to create complex and intricate PCB layouts. This software allows designers to quickly and accurately design flex rigid PCBs with multiple layers and intricate routing patterns, reducing the time and effort required to create a high-quality PCB design. By using this software, designers can experiment with different layouts and configurations, allowing them to optimize the performance and reliability of their electronic devices.

Furthermore, advancements in flex rigid PCB technology have also led to improvements in the overall performance of electronic devices.

By using flex rigid PCBs, designers can create electronic devices that are more compact, lightweight, and energy-efficient, without sacrificing performance or reliability. This has opened up new possibilities for a wide range of industries, from consumer electronics to medical devices, where space and weight constraints are critical factors.

Overall, the advancements in flex rigid PCB technology this month are a testament to the ongoing innovation and progress in the electronics industry.

By leveraging new materials, manufacturing processes, and design software, companies are pushing the boundaries of what is possible with flex rigid PCB technology, creating new opportunities for designers and engineers to create more compact, reliable, and high-performance electronic devices.

As we look towards the future, it is clear that flex rigid PCB technology will continue to play a crucial role in shaping the electronics industry.

With ongoing advancements and breakthroughs in materials, manufacturing processes, and design software, the possibilities for flex rigid PCB technology are endless. Designers and engineers can look forward to a future where electronic devices are smaller, lighter, and more reliable than ever before, thanks to the exciting developments in flex rigid PCB technology.