Advantages of Flex Rigid PCB Technology

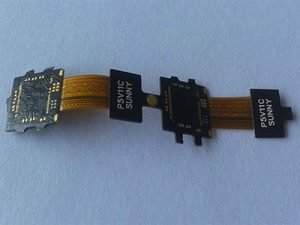

Flex rigid PCB technology has been making waves in the electronics industry, offering a range of advantages over traditional rigid PCBs.

These innovative circuit boards combine the flexibility of flexible circuits with the durability of rigid boards, opening up new possibilities for designers and engineers. In this article, we will explore the latest developments in flex rigid PCB technology and the advantages they offer.

One of the key advantages of flex rigid PCB technology is its ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, flex rigid PCBs allow for more compact and lightweight designs.

This is particularly important in industries such as aerospace and medical devices, where space and weight constraints are critical.

Another advantage of flex rigid PCB technology is its improved reliability and durability.

Traditional rigid PCBs are prone to failure due to factors such as vibration, shock, and thermal expansion.

Flex rigid PCBs, on the other hand, are designed to withstand these challenges, making them ideal for applications where reliability is paramount.

Flex rigid PCB technology also offers greater design flexibility.

Designers can create complex, three-dimensional shapes that would be impossible with traditional rigid boards.

This opens up new possibilities for innovative and creative product designs, allowing engineers to push the boundaries of what is possible in electronics.

In addition to these advantages, flex rigid PCB technology also offers cost savings.

While the initial investment in flex rigid PCBs may be higher than traditional rigid boards, the overall cost savings over the lifetime of the product can be significant. By reducing the need for additional components and assembly processes, flex rigid PCBs can streamline production and reduce manufacturing costs.

The latest developments in flex rigid PCB technology have further enhanced these advantages.

New materials and manufacturing techniques have improved the performance and reliability of flex rigid PCBs, making them even more attractive for a wide range of applications. For example, advances in material science have led to the development of flexible substrates that offer improved thermal conductivity and electrical performance.

Furthermore, advancements in manufacturing processes have made it easier and more cost-effective to produce flex rigid PCBs in high volumes.

This has opened up new opportunities for manufacturers to incorporate flex rigid technology into a wide range of products, from consumer electronics to automotive systems.

Overall, the latest developments in flex rigid PCB technology are breaking barriers and opening up new possibilities for designers and engineers.

With their compact size, improved reliability, design flexibility, and cost savings, flex rigid PCBs are poised to revolutionize the electronics industry.

As technology continues to evolve, we can expect to see even more exciting developments in flex rigid PCB technology in the years to come.